You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Does anyone here have a 3d printer?

- Thread starter Fatmarley

- Start date

Looks great  Just check the thickness of the ribs which form the hexes. The great thing is you’re not gonna lose much with some failed prints, but I think you might struggle to go thinner than about 0.7mm.

Just check the thickness of the ribs which form the hexes. The great thing is you’re not gonna lose much with some failed prints, but I think you might struggle to go thinner than about 0.7mm.

Also as @booja30 mentions, print setup is also critical. I’d be looking to print your design upside down with supports between the bed and print. I use Prusa slicer which has an option to auto-generate these, but I imagine most other slicers would have something similar.

Also as @booja30 mentions, print setup is also critical. I’d be looking to print your design upside down with supports between the bed and print. I use Prusa slicer which has an option to auto-generate these, but I imagine most other slicers would have something similar.

The other idea I was thinking while painting the living room was to print the cylinder and the dome separately. Make the cylinder have a ‘step’ inside, then the grille fits in the recess. Kind of like how a manhole cover rests in the opening.

If the dome was designed as a solid piece with the hex holes punched through it then it would not need any supports. Just print the cylinder and the dome separately and then glue them together.

If the dome was designed as a solid piece with the hex holes punched through it then it would not need any supports. Just print the cylinder and the dome separately and then glue them together.

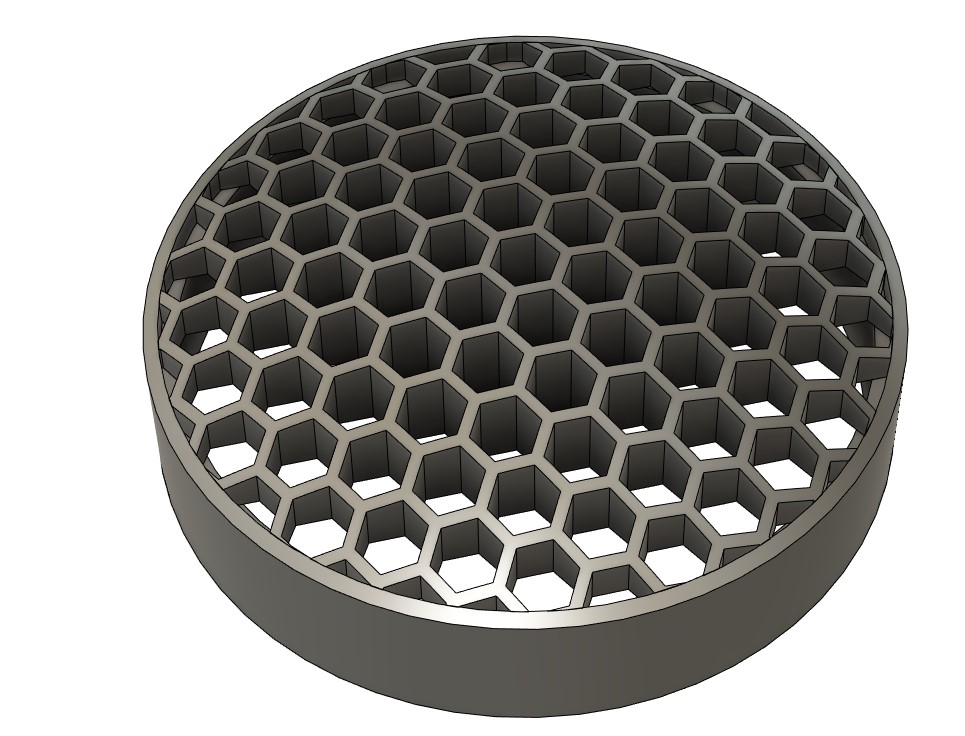

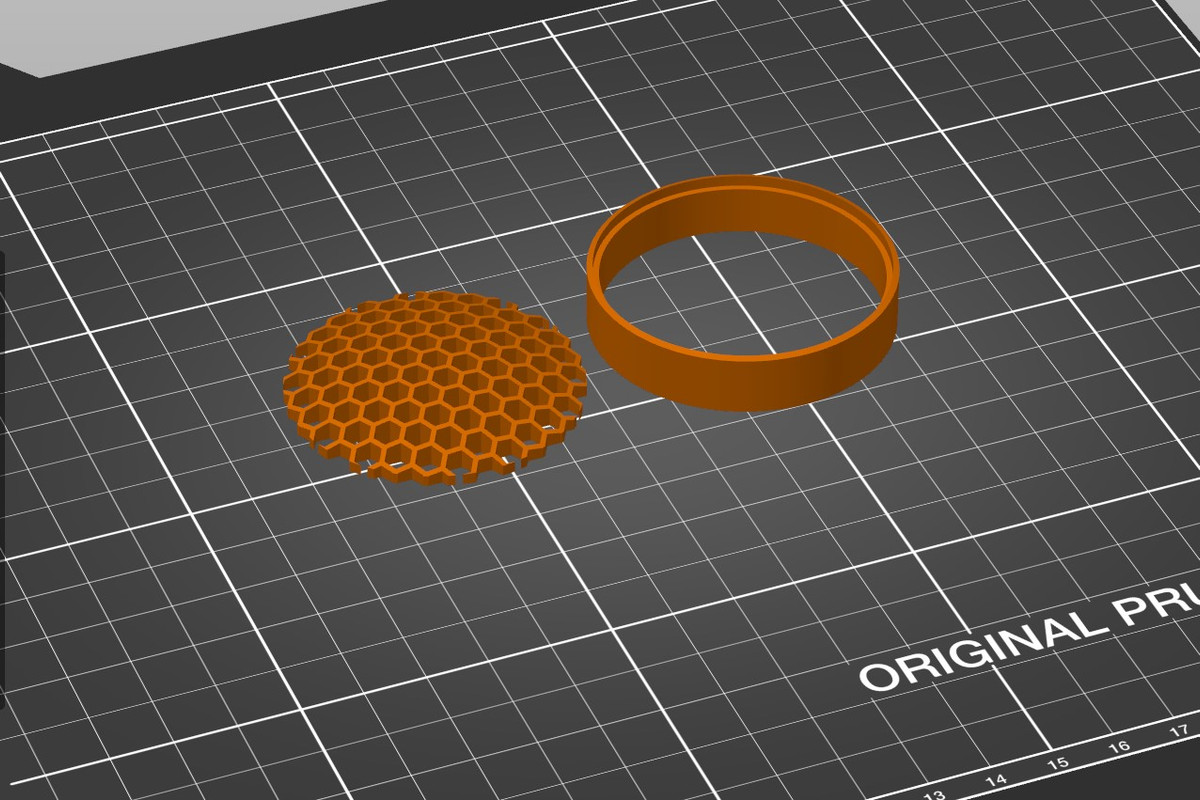

Here's what I described above. This would print without any supports since the hexagonal dome part isn't actually concave underneath.

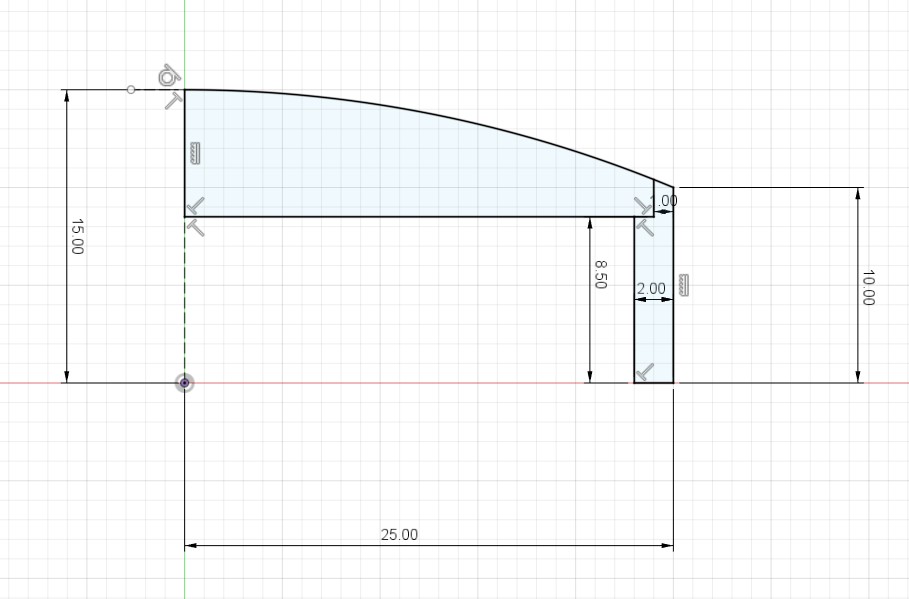

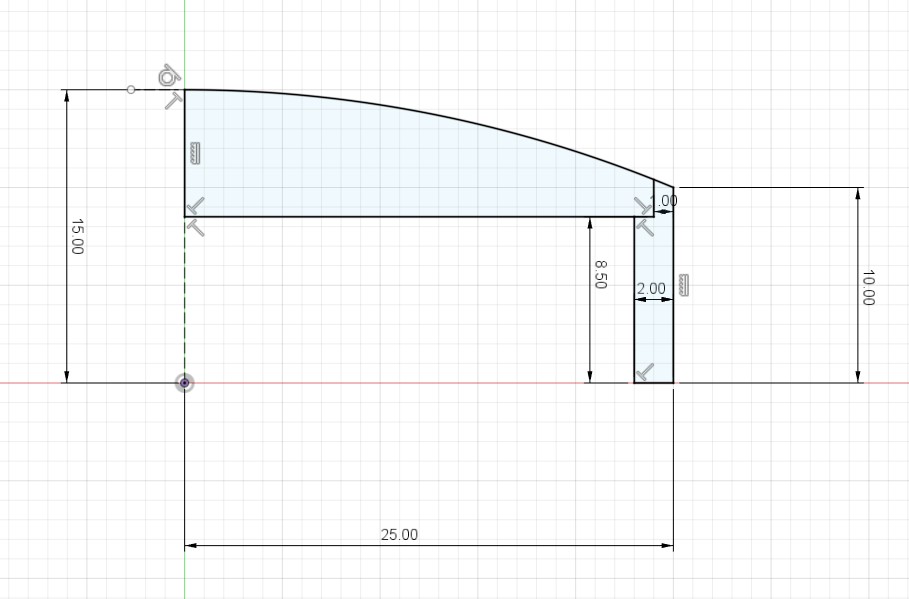

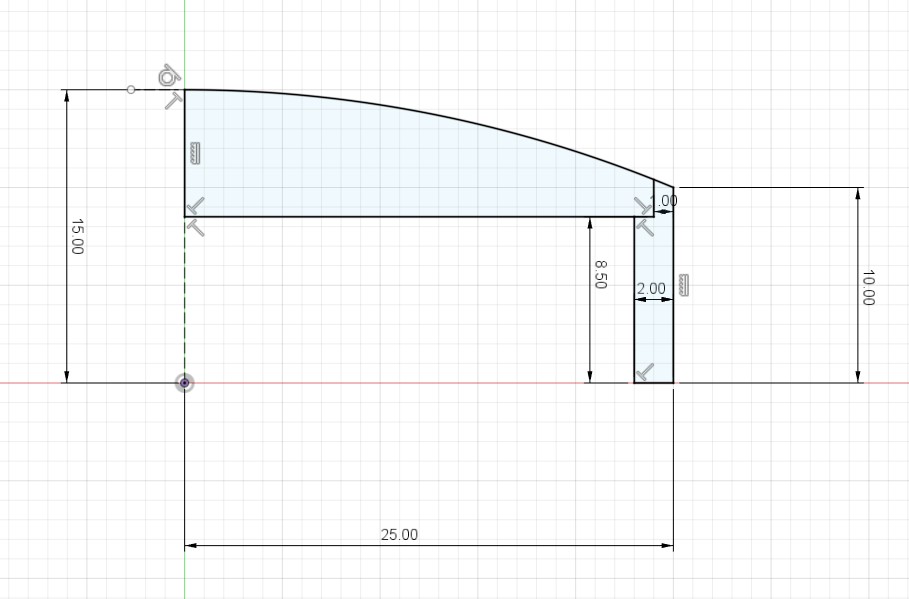

New sketch:

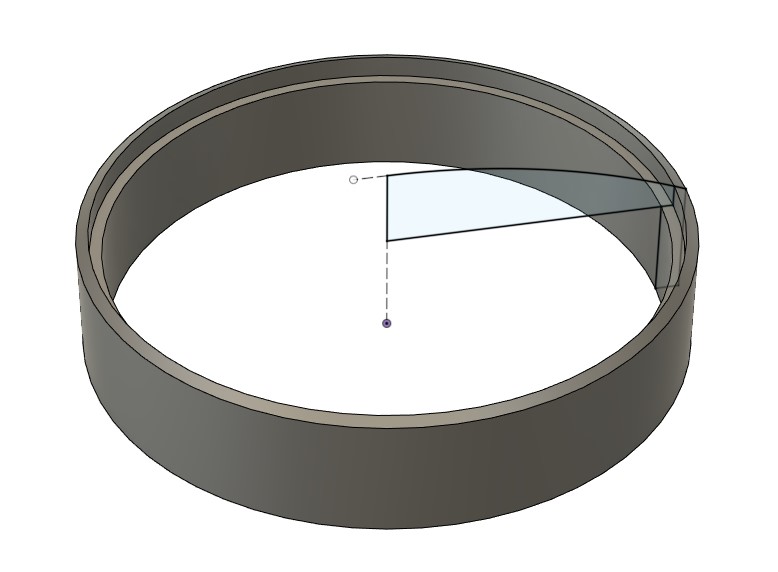

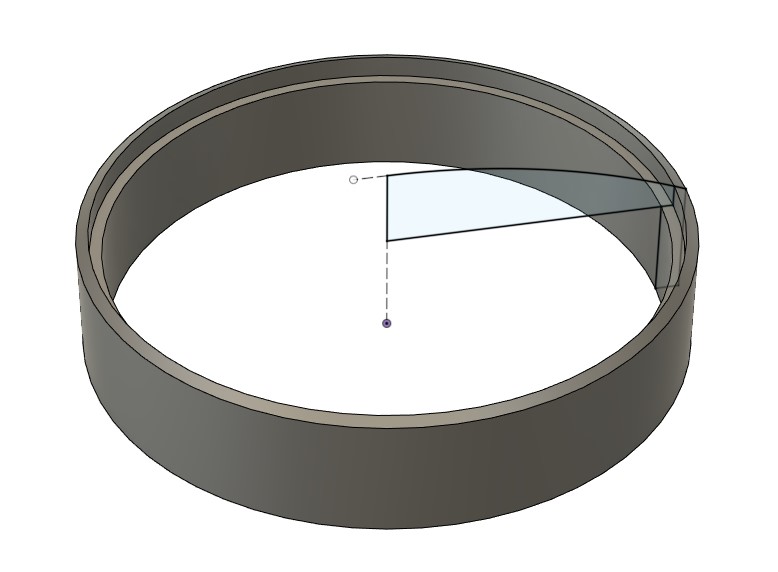

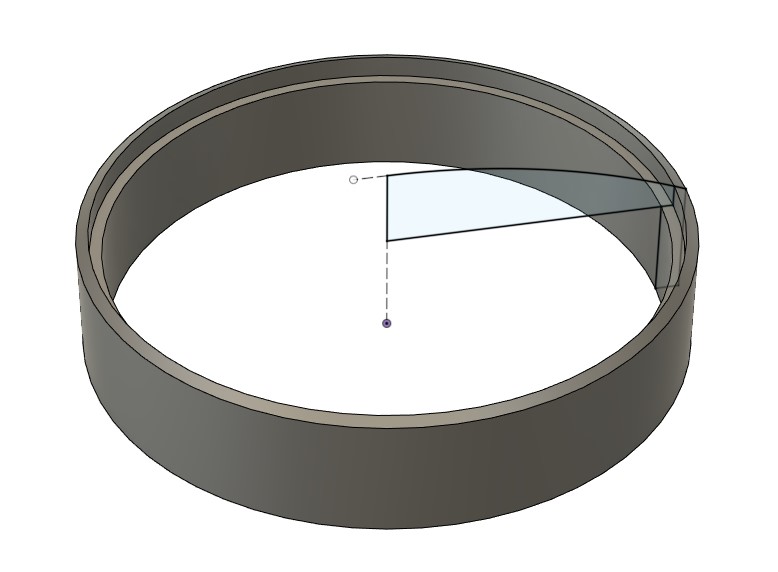

Revolve the stepped cylinder:

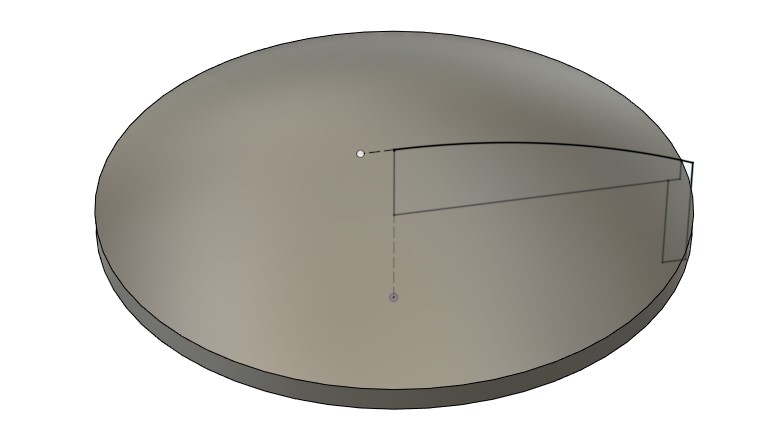

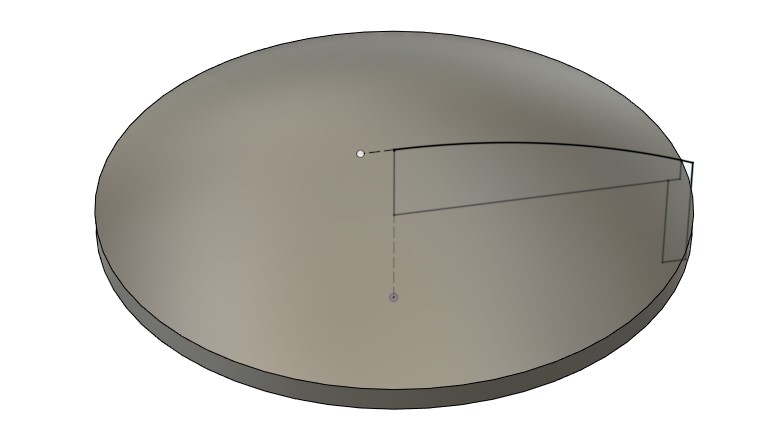

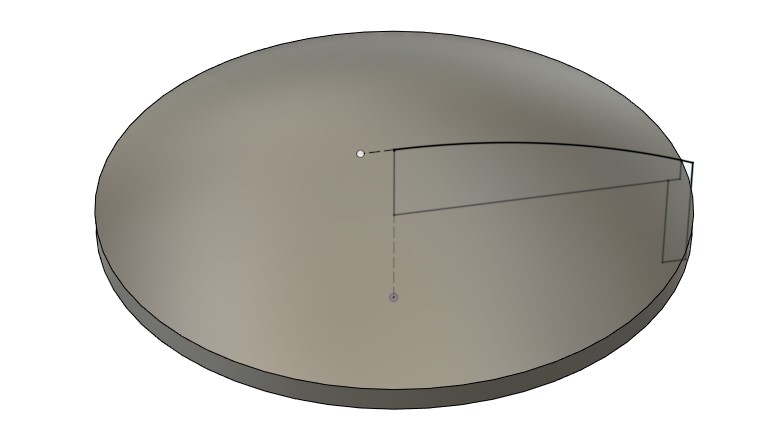

Revolve the dome:

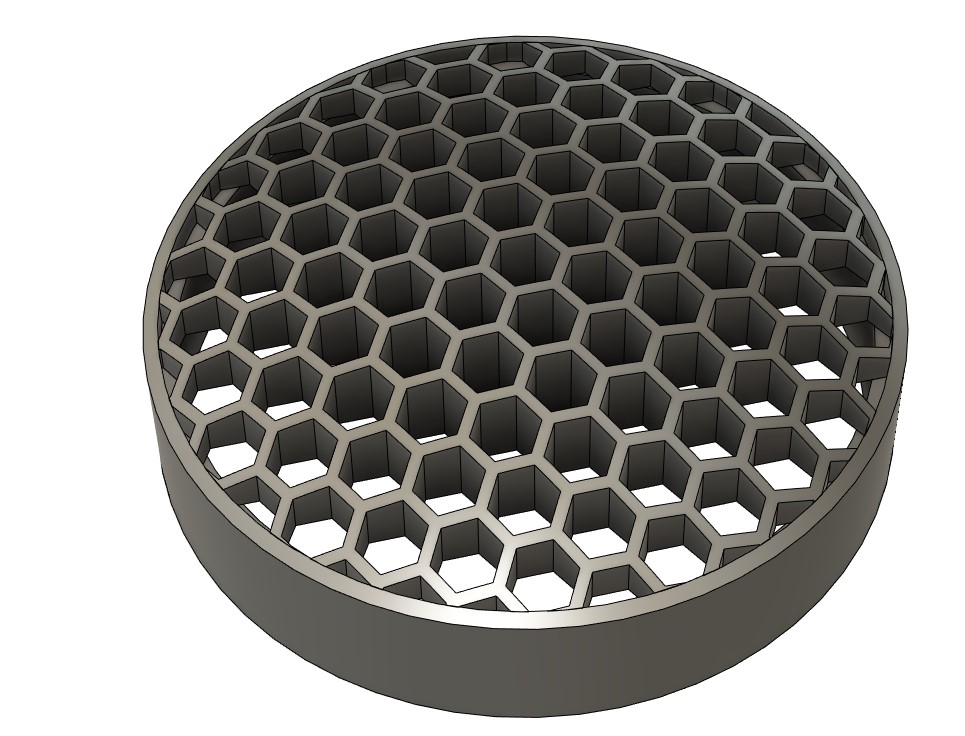

Cut the perforations from the dome only:

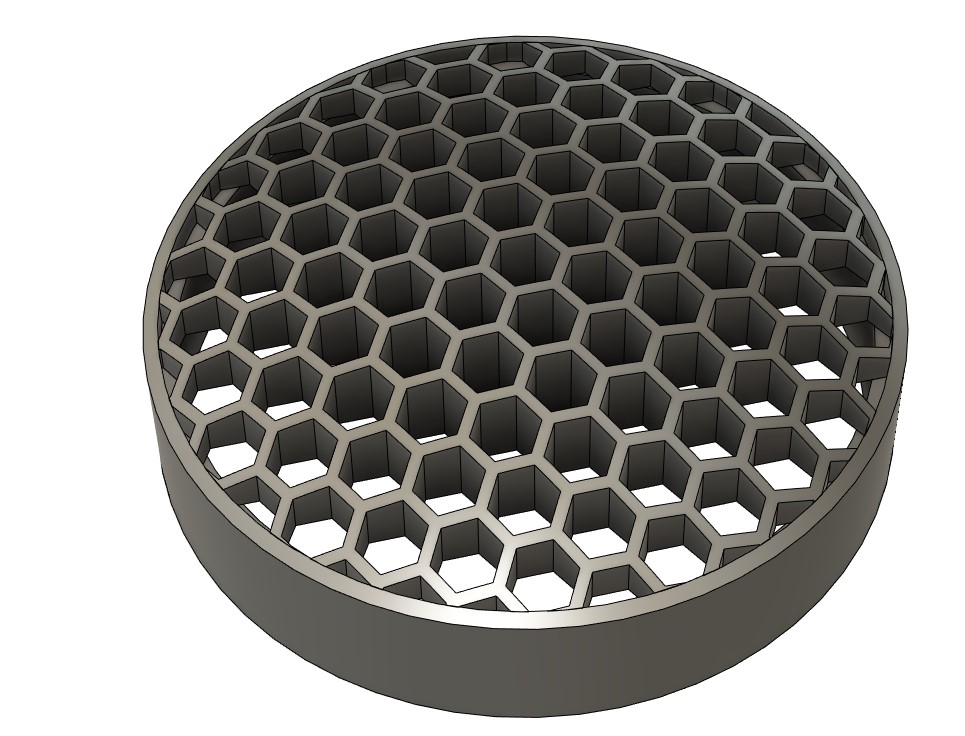

The two parts assembled:

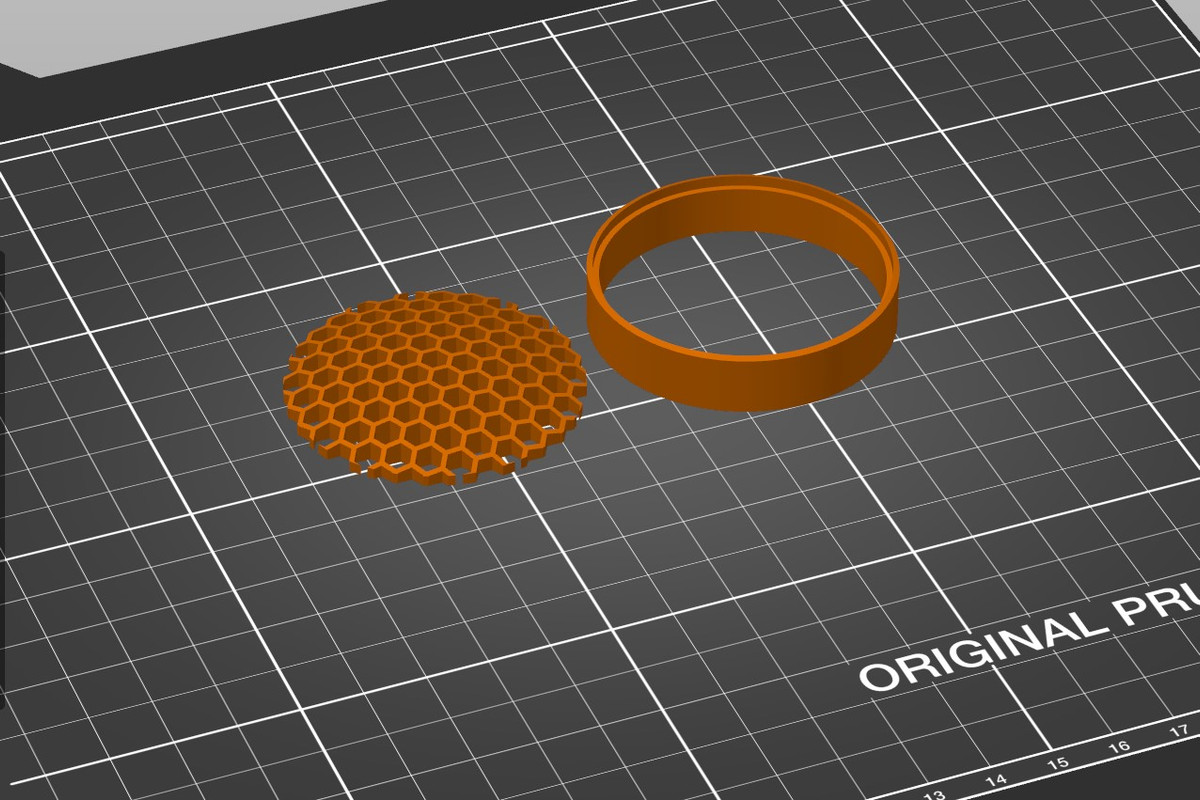

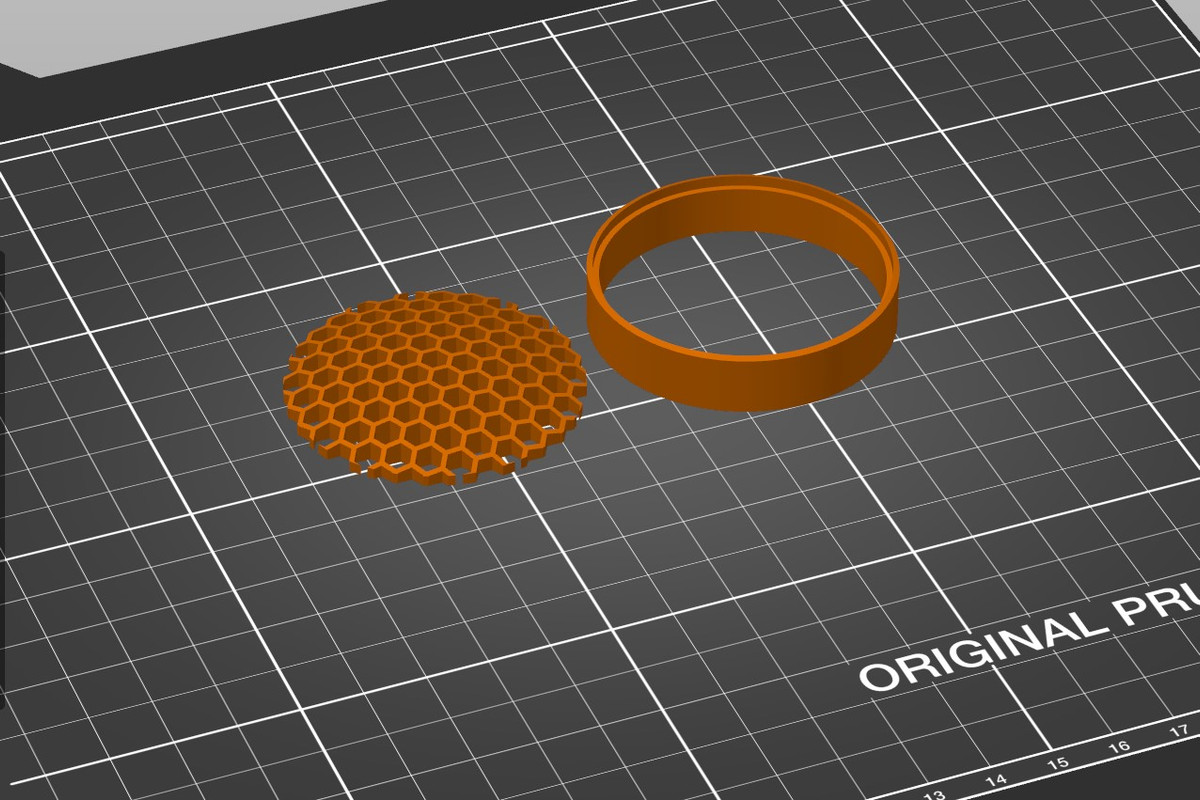

Loaded into the slicer software:

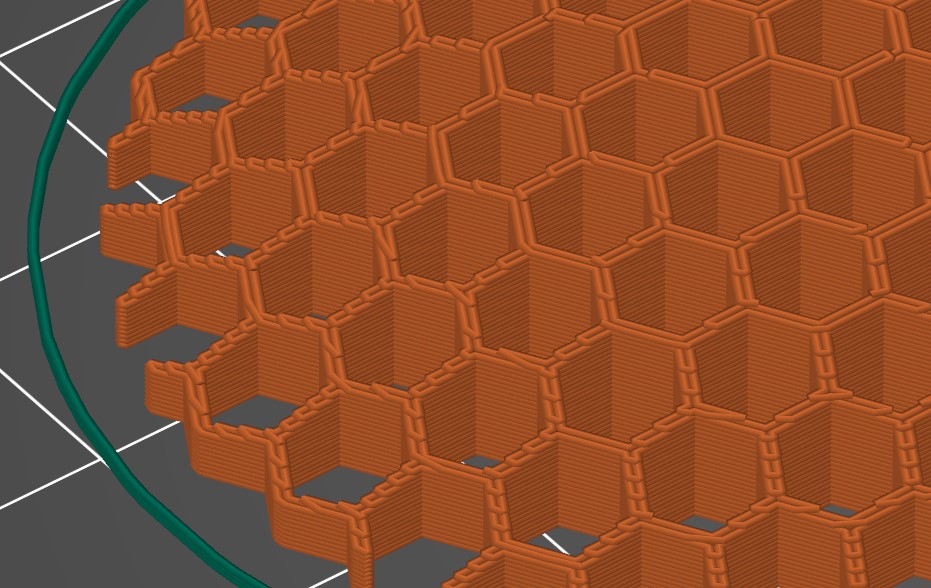

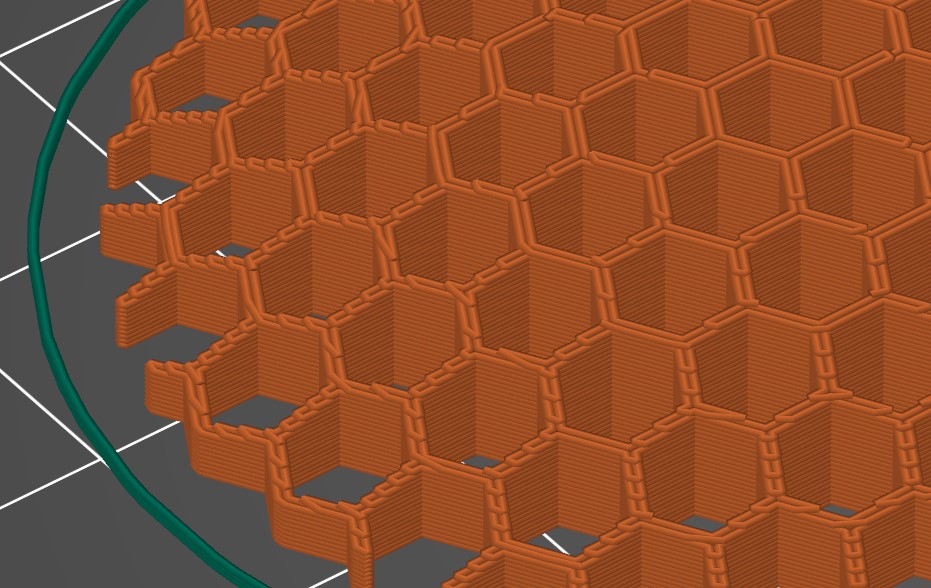

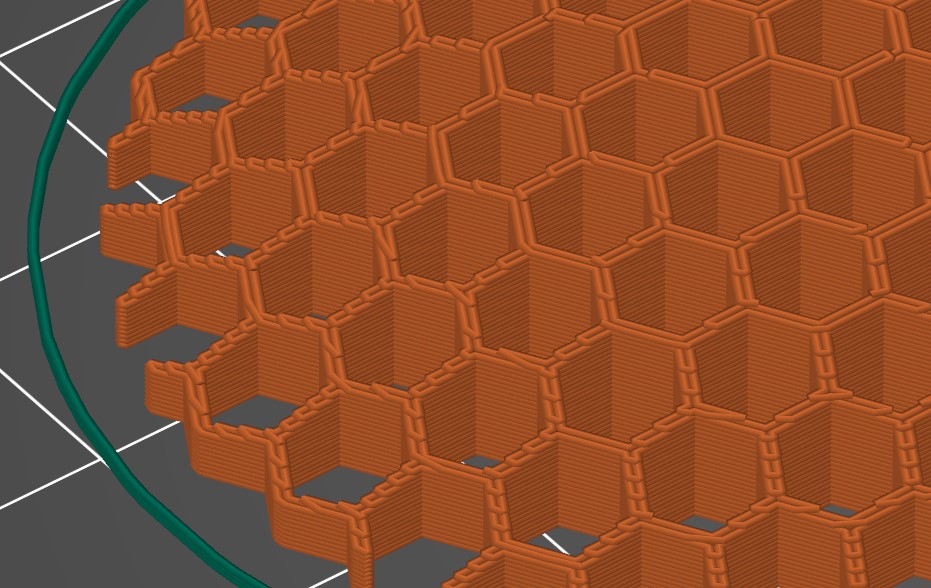

Closeup of the sliced model:

The slicer creates a rendering showing what is 'drawn' on each level by the printer. You can manipulate a slider and inspect each layer of the printed object to look for issues before printing.

Once you get good with Fusion 360 (even as a hobbyist like me) you can knock this kind of stuff out in 5-10 minutes. The printing become the bottleneck -- this model would take 45 minutes to print with a fairly large (0.2 mm a.k.a. low res) layer height.

New sketch:

Revolve the stepped cylinder:

Revolve the dome:

Cut the perforations from the dome only:

The two parts assembled:

Loaded into the slicer software:

Closeup of the sliced model:

The slicer creates a rendering showing what is 'drawn' on each level by the printer. You can manipulate a slider and inspect each layer of the printed object to look for issues before printing.

Once you get good with Fusion 360 (even as a hobbyist like me) you can knock this kind of stuff out in 5-10 minutes. The printing become the bottleneck -- this model would take 45 minutes to print with a fairly large (0.2 mm a.k.a. low res) layer height.

Fatmarley

"It appears my intelligence circuits have melted"

Looks greatJust check the thickness of the ribs which form the hexes. The great thing is you’re not gonna lose much with some failed prints, but I think you might struggle to go thinner than about 0.7mm.

Also as @booja30 mentions, print setup is also critical. I’d be looking to print your design upside down with supports between the bed and print. I use Prusa slicer which has an option to auto-generate these, but I imagine most other slicers would have something similar.

I didn't measure the ribs, just used copy and paste for the honeycomb and placed it somewhere that looked about right. I'll check the thickness when I get a chance.

It just goes to show how little I know about 3d printing - I didn't realise there was printing software to learn too. I'll have a look at Prusa slicer.

Fatmarley

"It appears my intelligence circuits have melted"

Here's what I described above. This would print without any supports since the hexagonal dome part isn't actually concave underneath.

New sketch:

Revolve the stepped cylinder:

Revolve the dome:

Cut the perforations from the dome only:

The two parts assembled:

Loaded into the slicer software:

Closeup of the sliced model:

The slicer creates a rendering showing what is 'drawn' on each level by the printer. You can manipulate a slider and inspect each layer of the printed object to look for issues before printing.

Once you get good with Fusion 360 (even as a hobbyist like me) you can knock this kind of stuff out in 5-10 minutes. The printing become the bottleneck -- this model would take 45 minutes to print with a fairly large (0.2 mm a.k.a. low res) layer height.

More great tips

I may try both ideas and see how they compare.

Fatmarley

"It appears my intelligence circuits have melted"

The GF has said she'll give me £250 towards a 3d printer as an early birthday present, so I could spend around £400 to £500. Any suggestions for this price range?

Also, what about the filament? What and where should I buy it from?

Is there anything else I should consider?

Also, what about the filament? What and where should I buy it from?

Is there anything else I should consider?

I was in a similar position a couple of months back so started this thread https://pinkfishmedia.net/forum/threads/3d-printing.275395/ The Prusa Mini has been excellent so far.

Again, the benefits of having your own printer will allow you to draw your own conclusions on this by trial and error, but having varying and relatively thick (~7mm) thick sections (as @booja30 is proposing) in front of the tweeter, is not ideal acoustically. But it is a good way to get around the print setup complications discussed previously

Again, the benefits of having your own printer will allow you to draw your own conclusions on this by trial and error, but having varying and relatively thick (~7mm) thick sections (as @booja30 is proposing) in front of the tweeter, is not ideal acoustically. But it is a good way to get around the print setup complications discussed previously

I also think the Prusa Mini would be a good option. Lots of support, great company, easy to get replacement parts.

For filament I would just look for a well rated PETG type on Amazon. PETG works great with the textured build plate, and it’s more durable than PLA. Prusa printers often come with a roll of grey PLA, and that’s good enough for getting familiar and experimenting.

ABS might be stronger than PLA and UV resistant, but you need a heated or insulated printer cabinet to keep air temps up. And it stinks so you would want good ventilation.

For filament I would just look for a well rated PETG type on Amazon. PETG works great with the textured build plate, and it’s more durable than PLA. Prusa printers often come with a roll of grey PLA, and that’s good enough for getting familiar and experimenting.

ABS might be stronger than PLA and UV resistant, but you need a heated or insulated printer cabinet to keep air temps up. And it stinks so you would want good ventilation.

cubastreet

Espresso Fiend

Prusa mini is great.

I've been hearing great things about Bambu lab, check them out too.

I've been hearing great things about Bambu lab, check them out too.

Fatmarley

"It appears my intelligence circuits have melted"

I was in a similar position a couple of months back so started this thread https://pinkfishmedia.net/forum/threads/3d-printing.275395/ The Prusa Mini has been excellent so far.

Again, the benefits of having your own printer will allow you to draw your own conclusions on this by trial and error, but having varying and relatively thick (~7mm) thick sections (as @booja30 is proposing) in front of the tweeter, is not ideal acoustically. But it is a good way to get around the print setup complications discussed previously

The Prusa mini does look good, it's just the small printing area that puts me off. Most other printers don't seem as reliable though, or at least, a bit of a lottery.

I did wonder how the thick front section of the dome cover would affect the sound. Also sticks out a bit, and not as tidy looking.

If I printed with the dome facing up, once the supports are removed, can the underside be smoothed with sandpaper or a dremel? I'm not worried about it being tidy underneath, just don't want anything sticking out that could damage the tweeter.

Fatmarley

"It appears my intelligence circuits have melted"

Prusa mini is great.

I've been hearing great things about Bambu lab, check them out too.

Yes, I've been researching printers and the Bambu lab printers get a lot of positive feedback. I'm tempted to save up for the P1P - https://bambulab.com/en/p1

The other great thing about the Bambu, is the possibility of adding AMS to produce multiple colours and dissolvable supports - https://uk.store.bambulab.com/products/ams-multicolor-printing

If you’re looking in the Bambu price range and want a bigger print area than the Prusa Mini then you might as well add the Prusa i3 MK3S kit to your list. It’s a workhorse, and it’s what Prusa themselves print all of their plastic parts on. That’s what I use. Assembling it yourself save some $$ and gets you familiar with how it works in case you have to replace a part or upgrade it down the road.

This is way out of date, but still pretty interesting:

2018:

2020:

This is way out of date, but still pretty interesting:

2018:

2020:

Last edited:

Fatmarley

"It appears my intelligence circuits have melted"

If I designed something that was bigger than the printer could print in one go, how much of a problem would that be?

Would it have to be sliced up in Fusion, or does the slicer software sort that problem?

I designed a loudspeaker enclosure last night, but it's 250mm wide x 400mm tall.

Would it have to be sliced up in Fusion, or does the slicer software sort that problem?

I designed a loudspeaker enclosure last night, but it's 250mm wide x 400mm tall.

IMO you would want to split up the part yourself in CAD so you have control over how the parts fit together, keys to align them and provide more surface area for glue, etc.

I think the bigger problem is how long it would take to print something like that. Also, the cost with filament being roughly $25/kg.

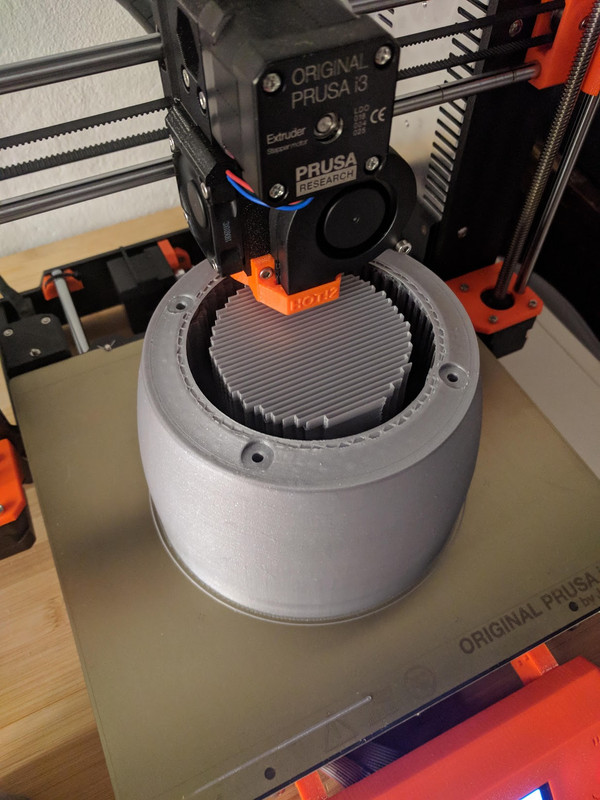

Back when I first started using my printer in 2018 someone on PFM wanted me to design and print a replacement for a shattered Tannoy magnet cover. Think large cereal bowl size. That print took over 24 hours and failed part way through!

I think the bigger problem is how long it would take to print something like that. Also, the cost with filament being roughly $25/kg.

Back when I first started using my printer in 2018 someone on PFM wanted me to design and print a replacement for a shattered Tannoy magnet cover. Think large cereal bowl size. That print took over 24 hours and failed part way through!

Fatmarley

"It appears my intelligence circuits have melted"

IMO you would want to split up the part yourself in CAD so you have control over how the parts fit together, keys to align them and provide more surface area for glue, etc.

I think the bigger problem is how long it would take to print something like that. Also, the cost with filament being roughly $25/kg.

Back when I first started using my printer in 2018 someone on PFM wanted me to design and print a replacement for a shattered Tannoy magnet cover. Think large cereal bowl size. That print took over 24 hours and failed part way through!

Oh, perhaps 3d printing a speaker is not a good idea then. Have you any idea how thin I could go on the walls, if I were to try it? Just wondering if I could 3d print the outside and fibreglass the inside.

The print on your Prusa failed?

I asked about printers over on Facebook Prusa and Bambu groups, and most people are recommending Prusa. Bambu is much faster to print, but Prusa is a safer bet.

The print on your Prusa failed?

It was a beginner's mistake. I didn't have some parameters set up correctly, and the supports weren't sufficient, so at some point a piece came loose and it started printing spaghetti all over. That's a pretty normal failure mode for any FDM printer.

I found a photo of it:

The center part was a support for the concave area at the top. The support came loose from the base plate and started wobbling. Knowing what I know now I would have probably designed it as two pieces glued together so that there would be no need for supports.

Here's the failed part next to the smashed original part:

The (wasteful) supports are in the background.

garyi

leave blank

cubastreet

Espresso Fiend

Another option would be to print a mold and fiberglass the whole thing.Just wondering if I could 3d print the outside and fibreglass the inside.