nitrous

pfm Member

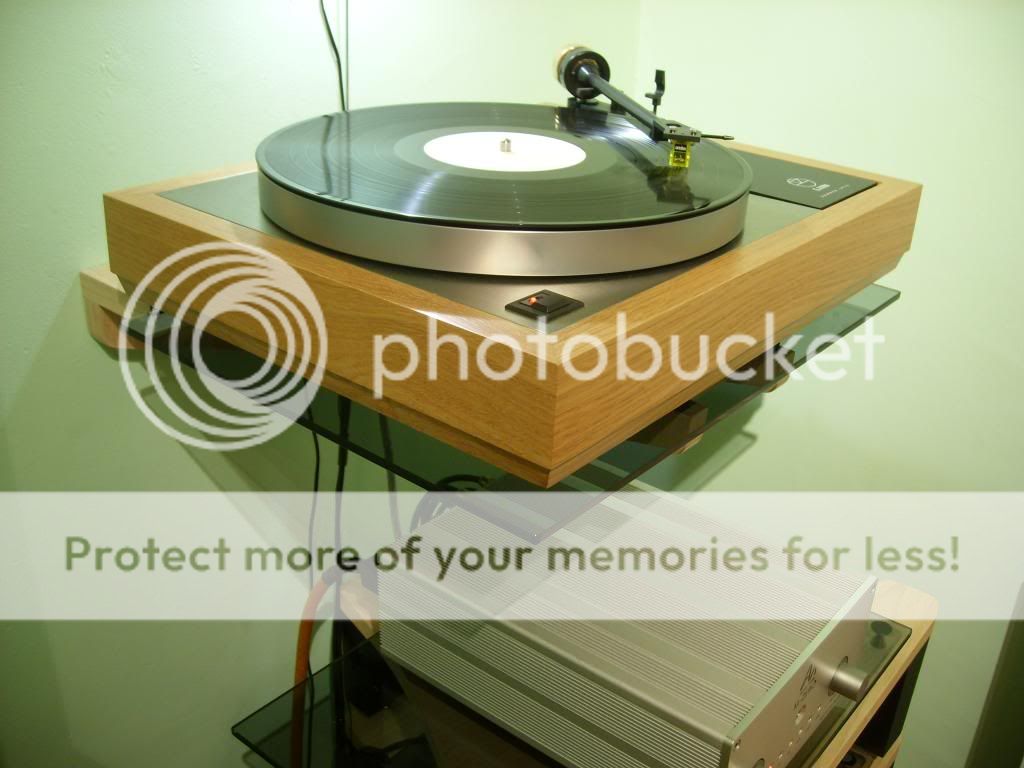

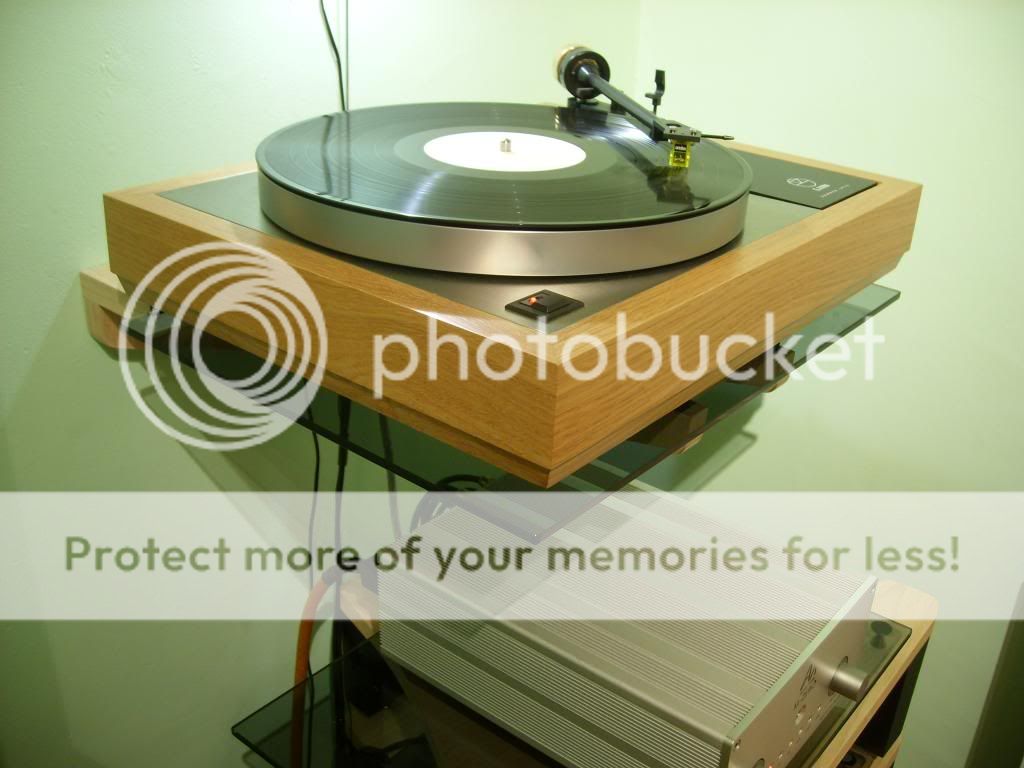

Dear Forum Members, Here is the culmination of a couple of months thinking and a bit of work.

The background:

I have never been terribly excited by the available 'off the peg' wall shelves, especially next to the something like Fraim or Fraim-a-like I therefore decided to try my hand at building something that was complimentary, and at least not an eyesore

I therefore decided to try my hand at building something that was complimentary, and at least not an eyesore .

.

I also wanted it to be fairly easy for other people to either DIY themselves or to have the confidence to try something similar. If people are interested I can give a little guidance on the design process and how I arrived at the end product, as I think this could be interesting for none designers.

As my No.2 LP 12 hasn't fallen of the wall in the last two days I have decided now is the time for the design to break cover. So some piccies

This is prototype so I would aim to get a better finish, plus the grain on veneer is running the wrong way on some pieces as they were left overs from the the last two fraim-a-like builds

I would be interested to know a) what people think of the design look, is it something they would have in there houses for instance? b) would people like me to publish some plans/guide ?

Look forward to hearing your responses, I have plenty piccies of build so will continue thread from beginning if interest is shown

Cheers nitrous

The background:

I have never been terribly excited by the available 'off the peg' wall shelves, especially next to the something like Fraim or Fraim-a-like

I also wanted it to be fairly easy for other people to either DIY themselves or to have the confidence to try something similar. If people are interested I can give a little guidance on the design process and how I arrived at the end product, as I think this could be interesting for none designers.

As my No.2 LP 12 hasn't fallen of the wall in the last two days I have decided now is the time for the design to break cover. So some piccies

This is prototype so I would aim to get a better finish, plus the grain on veneer is running the wrong way on some pieces as they were left overs from the the last two fraim-a-like builds

I would be interested to know a) what people think of the design look, is it something they would have in there houses for instance? b) would people like me to publish some plans/guide ?

Look forward to hearing your responses, I have plenty piccies of build so will continue thread from beginning if interest is shown

Cheers nitrous