h.g. This is in reply to you and a general note to other technical chaps who post here.

I won't be assessing the results except by ear, and if they need tweaking, then I can do that later. An added brace somewhere/ more or less damping or a change of damping density is easy to do.

What I asked for is help. Practical, simple advice to produce the best cabinet design for those drivers. It amazes me that after 60 odd years in production, a very close approximation to perfect isn't simply available as a set of plans.

I can see that engineers argue, and I can see that partnering kit and my room will be important variables, but I have no means of factoring these things into the design. When I built Wharfedale's Unit 4 speakers in 1970 ish, they came with crossovers, some wadding and a simple accurate box plan. I made them in a weekend, plugged them in and happily listened for nearly 20 years. That's where I'm at.

I am doing my best to take on board anything vital that would make them sound, lets say less that 95% of their potential, and I asked for as much help as possible in guiding a beginner and non Scientist to a happy ending.

Happy for the academics to argue about the fine stuff, but if they wish to be helpful, a summary ('Rocky, make sure the front baffle is recessed by 13.7mm') etc would be useful. Knowing why is of academic interest if I understood it, which I don't.

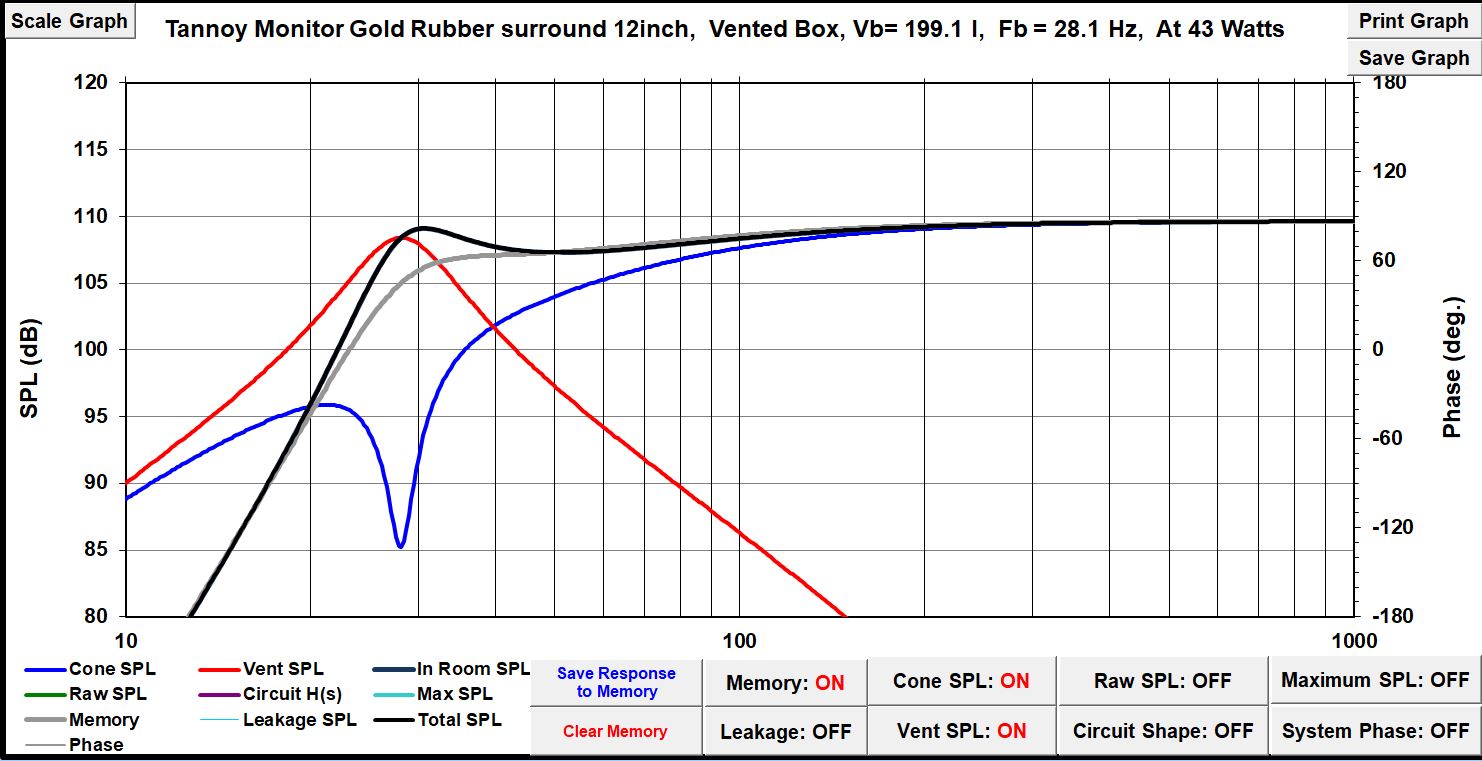

All I know is that I have coming, at some point, some 12"R monitor golds and their crossovers. I have NIL technical understanding or the equipment and although I do appreciate the things that can matter, It's a waste of your time posting things like this '

What does the baffle step look like with these dimensions? What does the edge diffraction look like given you will be reinforcing it with 3.5" on 3 edges? Where are the dips and valleys in the driver response which may guide the placement of the dips and valleys from edge diffraction? What are the dips and valleys from the crossover and how best to tweak them? What is the optimum off-axis angle to design for (coaxials typically have significant diffraction issues on axis which largely disappear 10-20 degrees off axis)?', because I have no idea at all what any of it means.

As to speed, no, there's no hurry. As I say, I am doing my best to gather the info from people who contribute and summarise it as I go. I imagine that, at some point, people will stop arguing and I'll take that silence as a meassage that I'm close enough

Thanks for contributing. I'm just trying to explain that your talking to a non technical person. Not stupid, just an engineering black hole.