You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are my Quad Esl 63s off colour?

- Thread starter eisenach

- Start date

DimitryZ

pfm Member

I never had to service them. Send the link to the website, please. I read somewhere that there is a hair drier trick if the Mylar gets slack in transit?I just read up at their site about DIY servicing the Eminent speakers........... it doesn't sound that straightforward !

And with that flaw in the design with the woofer, I'm not so sure about them.

How often do they need servicing?

What ? You have to use a hair dryer to repair a fault from transit damage. Those speakers sound a bit fragile.

I'm really going off the idea of these.

Surprised you don't know about all the service instructions on their site, let me point you to it

http://www.eminent-tech.com/main.html

Is that them?

I'm really going off the idea of these.

Surprised you don't know about all the service instructions on their site, let me point you to it

http://www.eminent-tech.com/main.html

Is that them?

DimitryZ

pfm Member

Oh sure...that's instructions on replacing the tweeter drivers if you blow them, I guess. This would be like replacing the Magnepan ribbon, which I had to do. Very easy, the speakers are open front and back, two wires, can be done without moving the speaker at all. About 1/2 hour of work per side.What ? You have to use a hair dryer to repair a fault from transit damage. Those speakers sound a bit fragile.

I'm really going off the idea of these.

Surprised you don't know about all the service instructions on their site, let me point you to it

http://www.eminent-tech.com/main.html

Is that them?

It also could be referring to the tweeter replacement that happened many years ago when 8A tweeter was replaced by 8B, of higher sensitivity. I have never heard of these needing service, to be honest. One could damage them by handling a steel object very near the drivers, due to the very high magnetic field - the object can be pulled from your hands and puncture the driver.

But I think you are right, you probably don't need these speakers. You will probably damage them yourself, so you can post the pictures here as proof that "they need servicing, just like Quads."

Dowser

Learning to bodge again..

After being on garden leave for 7 months, I just started a new job this week and haven’t had time to look at PFM until now...

Dimitry - are 988s different from 63s? When the panel glue failed on my 63s there was no need to turn them over - simply remove top, sock, and away you go.

Replacing binding posts and the input capacitor does require speaker to be inverted, but is equally straightforward.

Both of above I did in my living room, without scope...just screw drivers and soldering iron. There are threads in DIY or Classic from me confirming both.

As for 1950s design, I think you’re confusing 57s with 63s? 57s are completely different to 63s, and panel repair is pretty much out of scope of DIY on the 57 (IMO and experience, I do know some people have done it, but don’t consider it within capabilities of most). 63 and later panels address this design limitation in my view, that allow the likes of you and I to also maintain them.

Honestly, if you could rebuild those super tweeters you kindly sent me (soon to be fixed finally I hope!), then I really don’t understand your aversion to servicing the 63s. However, to be clear I only paid £300 for my pair 2nd hand pair, am a complete cheapskate, and would write them off before spending a large sum on 3rd party service

Having owned both 57s and 63s, I cant imaging not owning a pair of some sort! And 63 and later models are much simpler to maintain...well, panels at least

Dimitry - are 988s different from 63s? When the panel glue failed on my 63s there was no need to turn them over - simply remove top, sock, and away you go.

Replacing binding posts and the input capacitor does require speaker to be inverted, but is equally straightforward.

Both of above I did in my living room, without scope...just screw drivers and soldering iron. There are threads in DIY or Classic from me confirming both.

As for 1950s design, I think you’re confusing 57s with 63s? 57s are completely different to 63s, and panel repair is pretty much out of scope of DIY on the 57 (IMO and experience, I do know some people have done it, but don’t consider it within capabilities of most). 63 and later panels address this design limitation in my view, that allow the likes of you and I to also maintain them.

Honestly, if you could rebuild those super tweeters you kindly sent me (soon to be fixed finally I hope!), then I really don’t understand your aversion to servicing the 63s. However, to be clear I only paid £300 for my pair 2nd hand pair, am a complete cheapskate, and would write them off before spending a large sum on 3rd party service

Having owned both 57s and 63s, I cant imaging not owning a pair of some sort! And 63 and later models are much simpler to maintain...well, panels at least

DimitryZ

pfm Member

I owned both 57 and 988 and worked on both.After being on garden leave for 7 months, I just started a new job this week and haven’t had time to look at PFM until now...

Dimitry - are 988s different from 63s? When the panel glue failed on my 63s there was no need to turn them over - simply remove top, sock, and away you go.

Replacing binding posts and the input capacitor does require speaker to be inverted, but is equally straightforward.

Both of above I did in my living room, without scope...just screw drivers and soldering iron. There are threads in DIY or Classic from me confirming both.

As for 1950s design, I think you’re confusing 57s with 63s? 57s are completely different to 63s, and panel repair is pretty much out of scope of DIY on the 57 (IMO and experience, I do know some people have done it, but don’t consider it within capabilities of most). 63 and later panels address this design limitation in my view, that allow the likes of you and I to also maintain them.

Honestly, if you could rebuild those super tweeters you kindly sent me (soon to be fixed finally I hope!), then I really don’t understand your aversion to servicing the 63s. However, to be clear I only paid £300 for my pair 2nd hand pair, am a complete cheapskate, and would write them off before spending a large sum on 3rd party service

Having owned both 57s and 63s, I cant imaging not owning a pair of some sort! And 63 and later models are much simpler to maintain...well, panels at least

Both models were very difficult to work on and were not made for easy pro service and/or owner service.

Neither speaker allows for owner panel refurbishment. Arguably, 63/988 allows for panel replacement, but the speaker requires near full dis-assembly, with the top section removed from the base, which requires multiple desolodering and structural partition. I never owned or worked on the 63, but the process should be very similar. There's also a very large number of solder joints to make in order to replace the panels, the exact number quoted earlier in the thread.

Binding post replacement and cap bypass is straightforward if laborious and hand lacerating. That is the extent of Quad owner modification that most people will/should do.

I have long maintained that Quad should have updated the manufacturing approach to 21st century, instead of simply replicating original 1950s garage style build that Peter Walker envisioned. Sadly, they have long lost any understanding of what they are building, blindingly repeating the exact 63 recipe ad nuseum.

Additionally, they should have realized (duh) obvious fragility of the speakers and changed the design for easy panel replacement by the owner without moving the speakers and soldering. Alas, this would require real engineering, that the company obviously was not ready to implement.

Enjoy the supertweeters. Fixing those is super easy compared to the Quads. They are a pound each and less the a cubic foot in volume.

Robert

Tapehead

Bad luck. It's not a good time of year for it to happen, is it? Hope you get it fixed easily.

On a quick count I do have 11 other pairs of 'speakers knocking around so not too much of a hardship

Some lovely sounding gems in there such as the Meridian M2, ESL57, AR4xa and my own BMR based design, so I won't be without good sound.

camverton

pfm Member

Really Dimitry, I realise you have a drum to bang but “public service” it is not.

From personal experience, the panels on both 57s and 63s can be replaced at home by any reasonably competent person with decent soldering skills. I’ve done it a number of times on each model (too many times, which is one reason I moved to Martin Logans). The main requirements are common sense and a reasonably methodical method of working. Admittedly this will mean that some won’t be able to service their own Quads.

Of course my practical, and successful, experience obviously doesn’t count for much compared to people who have partially dismantled the speakers and discovered they weren’t up to the job. That is a reflection more of them than the speakers.

Having owned one pair of 57s and two pairs of 63s my tuppence worth is if buying secondhand factor in the costs and inconvenience of a full service (unless their policy has changed Quad became reluctant to sell spare panels) or buy new and hopefully have 10 or more years of trouble free sublime listening. They are expensive but if compared with comparable electrostatics or perhaps MBLs they could almost be considered a bargain .

.

From personal experience, the panels on both 57s and 63s can be replaced at home by any reasonably competent person with decent soldering skills. I’ve done it a number of times on each model (too many times, which is one reason I moved to Martin Logans). The main requirements are common sense and a reasonably methodical method of working. Admittedly this will mean that some won’t be able to service their own Quads.

Of course my practical, and successful, experience obviously doesn’t count for much compared to people who have partially dismantled the speakers and discovered they weren’t up to the job. That is a reflection more of them than the speakers.

Having owned one pair of 57s and two pairs of 63s my tuppence worth is if buying secondhand factor in the costs and inconvenience of a full service (unless their policy has changed Quad became reluctant to sell spare panels) or buy new and hopefully have 10 or more years of trouble free sublime listening. They are expensive but if compared with comparable electrostatics or perhaps MBLs they could almost be considered a bargain

DimitryZ

pfm Member

Obvious and easily observed evidence clearly contradicts your assertion that home service of Quads is within practical reach of most owners. The "invisible hand of the market" demonstrates that a number of specialty businesses are setup near any reasonable concentration of Quad owners in order to perform the "easy" self service you describe. This is absent for any other speaker brand. Ergo we can conclude that:Really Dimitry, I realise you have a drum to bang but “public service” it is not.

From personal experience, the panels on both 57s and 63s can be replaced at home by any reasonably competent person with decent soldering skills. I’ve done it a number of times on each model (too many times, which is one reason I moved to Martin Logans). The main requirements are common sense and a reasonably methodical method of working. Admittedly this will mean that some won’t be able to service their own Quads.

Of course my practical, and successful, experience obviously doesn’t count for much compared to people who have partially dismantled the speakers and discovered they weren’t up to the job. That is a reflection more of them than the speakers.

Having owned one pair of 57s and two pairs of 63s my tuppence worth is if buying secondhand factor in the costs and inconvenience of a full service (unless their policy has changed Quad became reluctant to sell spare panels) or buy new and hopefully have 10 or more years of trouble free sublime listening. They are expensive but if compared with comparable electrostatics or perhaps MBLs they could almost be considered a bargain.

1. Quads require service at shorter intervals than other speakers.

2. Most people who own them pay specialists to perform said service.

3. Owners like Quads and keep them a long time.

As i said many times before, if i lived within an easy drive distance of such a service provider, i would certainly own them.

Another way for people like me to own them is for the company to redesign the speaker for actual, honest to god self service by the user. But they will never do that because they only know one recipe.

DimitryZ

pfm Member

Anything is possible, given time, acquired skill and patience. One can service and repair one's car at the curb with essentially hand tools. One can learn how to sweat pipes well and do all the plumbing repair. One can become an amateur electrician, learn the local code and repair the house wiring.The biggest hassle servicing quads is the space they take up once stripped. Anything short of a new membrane is easily home serviced by any moderately practical and methodical bodger.

In practice, great majority of people choose to specialize in their professional avocation, since most of us are not wealthy and must actually be good at something so we are paid for work. Since our time is limited, we must select how to spend it. It is self-evident that a person who buys Quads at a dealer at the asking price is a proffessional, well-paid individual, who can afford the very high price. This person does not repair their car at the curb or sweat pipe unless expressly by choice, as a hobby. The hobbies this person has is unlikely to include soldering 100 solder joints in a stripped speaker in his/her living room. They unsurprisingly expect their expensive system to work flawlessly, not to produce hiss, pop or machine gun noise.

Once the Quad behavior is understood, the speakers are usually sold for pennies on the dollar by the original buyer, which explains the tons of "handyman special" Quads available all the time and proliferation of shops to repair and resell them.

I find the idea that owner refurbishment as the expected Quad ownership pattern to be both absurd and insulting. When i am off work, my time is far better spent with my actual chosen hobbies, such as music listening and photography. I do NOT want to strip my speakers and unsolder/resolder 100 joints as required part of owning $10k speakers (and pay $3.5k for new panels.)

Again, i say all of this with sadness. I would like to own Quads, but the design and company policy prevents me from doing so.

Last edited:

misterdog

Not the canine kind

Sorry I was referring to the Quad father.

Speaking of whom

Though you are not a consumer you are an engineer working at the cutting edge of science (or so you keep telling us), this seems to preclude you from the ability to use a Phillips screwdriver and a soldering iron which are the only tools required to maintain the Quad ESL.

Perhaps you are a software engineer ?

Perhaps philately would be a more suitable hobby then ? 20Kg is the average weight of any top class speaker many weigh considerably more.

Slacking off 8 x 4mm nuts must be extremely challenging to an engineer of your esteem.

Which is why so many Quad 57's are still in use after 62 years

Pray enlighten us how these solder joints are of inferior quality.

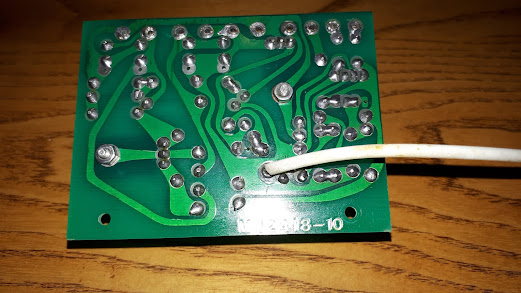

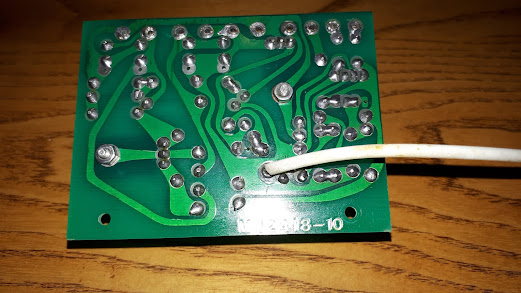

This is an input board I have removed from a Quad 63.

Speaking of whom

Quad is a very special speaker, which requires special maintenance, well in excess oftypicalmy consumer expectations.

Though you are not a consumer you are an engineer working at the cutting edge of science (or so you keep telling us), this seems to preclude you from the ability to use a Phillips screwdriver and a soldering iron which are the only tools required to maintain the Quad ESL.

Perhaps you are a software engineer ?

I found the process of boxing the speakers very laborious and very hard on my back. Dragging them out from the house and putting them on the shipping pallet was equally back breaking

Perhaps philately would be a more suitable hobby then ? 20Kg is the average weight of any top class speaker many weigh considerably more.

Separating the top of the speaker from the bottom was difficult and extremely unwieldy.

Slacking off 8 x 4mm nuts must be extremely challenging to an engineer of your esteem.

My irritation is not with the speaker as such, but with the company's utter inability to make it into a reliable, sellable product, either through a reliability redesign or through a reparability redesign for 50 YEARS.

Which is why so many Quad 57's are still in use after 62 years

In my experience, 988 circuit boards were of generally poor quality both in terms of manufacture and solder joint quality

Pray enlighten us how these solder joints are of inferior quality.

This is an input board I have removed from a Quad 63.

DimitryZ

pfm Member

Your first three attempts at retorts dont have any identifiable information content, so there is nothing to respond to.Sorry I was referring to the Quad father.

Speaking of whom

Though you are not a consumer you are an engineer working at the cutting edge of science (or so you keep telling us), this seems to preclude you from the ability to use a Phillips screwdriver and a soldering iron which are the only tools required to maintain the Quad ESL.

Perhaps you are a software engineer ?

Perhaps philately would be a more suitable hobby then ? 20Kg is the average weight of any top class speaker many weigh considerably more.

Slacking off 8 x 4mm nuts must be extremely challenging to an engineer of your esteem.

Which is why so many Quad 57's are still in use after 62 years

Pray enlighten us how these solder joints are of inferior quality.

This is an input board I have removed from a Quad 63.

The board that you apparently proudly posted a picture of is, in fact, an atrocious example of low skill, garage style manufacture. First, the artwork is clearly manually created, which is a clear indication that it is not optimized and that the company doesnt take their PWBs seriously enough to invest in actual design software. This board exhibits several significant solder joint flaws:

1. Most joints exhibit way too much solder volume, indicating inadequate training of the worker. Correct solder fillet is a concave meniscus, not a shapeless blob.

2. Upper jounts appear inadequately flowed - semi-cold, same problem as above.

3. Wire connection is devoid of secondary restraint. This connection is likely to fail under even mild levels of transport vibe.

4. The wire material used by Quad has a quite brittle conductor, exacerbating above.

5. The board is not adequately supported at all corners. This leads to vibration amplification and fatigue.

It is obvious you have not seen an actual high quality modern PWB.

misterdog

Not the canine kind

It is obvious you have not seen an actual high quality modern PWB.

Like my pre- amp I built for instance designed by Bruno Putzeys.

Or the 4 layer PCB of the Audiolab MDAC on which I have replaced most of the failed Lelon caps

So no Dimitry I know nothing about electrical engineering.

I can however strip and rebuild a Quad ESL and have done 7 so at least I know what I am talking about from practical experience.

If you wish to allow me to continue embarrassing myself please carry on.