You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Amp upgrade for Wharfedale Diamond 220 speakers

- Thread starter RobGordon

- Start date

RobGordon

Well-Known Member

Was thinking of using something to support it as per Fergus, but probably not toilet rolls, something more stable!I meant at your own risk.

I've flipped 100s of decks on their lids and have yet to damage a single one. This including SL-1200 Mk2 @ 12.5kg (although the arm clearance bubble makes a thick slab of foam rubber a better bench cover with these).

YMMV.

P.S. The merest thought of using toilet rolls makes my arse clench!

Not for the while though, just for future reference.

RobGordon

Well-Known Member

It was an AS-301, apparently, but not used with the Wharfedales apparently since it looks like I bought those 4 months later. It would have been tried with some slightly knackered 80s Technics speakers, and briefly some 90s Sony Speakers I use for laptop audio. It sounded (to me!) vastly inferior to the 80s Technics midi amp it replaced (an SU-x900 or 950), which worked well with the matching speakers and to date I have not bettered the sound. The turntable at the time was a Vestax PDX2000 Mk II, running a T4P cartridge for years because I'd been misinformed this was a good idea for the short, straight arm - did sound good enough though.I'd be grateful if you could name the model. My Yamaha amplifier, a budget AV receiver, came with two pairs of said Diamond 9.1s. I was expecting rubbish but it quite exceeded my expectations and turned out to be a very good match for the speakers. It's as detailed as the Rotel and dynamic enough. Its small soundstage is the only real issue I have with it, so I've become interested in proper 2-channel Yamaha amplifiers: I've heard some very good ones.

Looking at current prices of that Yamaha amp, they've gone up by 50%, so people must like them. Since I did not try with the Wharfedales, instead some tired old speakers that don't have the greatest rep (apparently Technics did not make good speakers, so says vinylengine), maybe disregard my opinion. I think the Wharfedales sound better but my current problem is the amp, keen to try this Rotel.

RobGordon

Well-Known Member

Damn that's what I buy, the latter I mean. The two-ply is surprisingly good value I'll have you know!May as well buy a Linn jig than that posh bog roll from Waitrose!

RobGordon

Well-Known Member

I was waiting to update you guys on hopefully my new amp, but for various reasons involving the ebay seller being incapacitated, the listing turning out to be incorrect, and his 17-year old son never sending the amp out in the first place, I don't have anything but a refund two weeks' on. This is typical of my luck on ebay, both buying and selling.

There is an RA-12 at just over £300, with remote and optical DAC that could be an improvement on my cheap Fiio. Seeing as I was eyeing up a DAC upgrade it could be within budget, maybe. It's a newer model though - I know Rotels, although made in China, have quality components historically but still don't trust something so new.

A local guy I buy records from was visibly a bit appalled when I told him what speakers I have, so there's another listing of interest, an RA-02 with unknown Tannoy speakers (new listing under construction) for about £350.

Or maybe I should cool off and watch local "collection only" offers. That's the way to get a bargain. Not much coming up over the last two weeks however.

Edit: and now there is a 1995 Pioneer A-204R offered at a bargain price. But being so old maybe it will require recapping and whatnot. Sorry about all this!

There is an RA-12 at just over £300, with remote and optical DAC that could be an improvement on my cheap Fiio. Seeing as I was eyeing up a DAC upgrade it could be within budget, maybe. It's a newer model though - I know Rotels, although made in China, have quality components historically but still don't trust something so new.

A local guy I buy records from was visibly a bit appalled when I told him what speakers I have, so there's another listing of interest, an RA-02 with unknown Tannoy speakers (new listing under construction) for about £350.

Or maybe I should cool off and watch local "collection only" offers. That's the way to get a bargain. Not much coming up over the last two weeks however.

Edit: and now there is a 1995 Pioneer A-204R offered at a bargain price. But being so old maybe it will require recapping and whatnot. Sorry about all this!

Salamander

pfm Member

Sorry about the Rotel, there is an Onkyo on bids, only 4hrs left Onkyo A-9110 amplifier | eBay

This site contains affiliate links for which pink fish media may be compensated.

RobGordon

Well-Known Member

Wow very interesting, only 10 hours use?? This might be the one. Or there's a NAD C320BEE finishing soon as well, if the price doesn't go too high there's a £60 phono stage I've owned before that I'd be happy to use with it.Sorry about the Rotel, there is an Onkyo on bids, only 4hrs left Onkyo A-9110 amplifier | eBay

This site contains affiliate links for which pink fish media may be compensated.

G.smith310

pfm Member

Cannot go wrong with Yamaha AS series or Denon PMA series when it comes to great value sound and functionality

Salamander

pfm Member

The Onkyo went for a good price £122 + £15 postage

RobGordon

Well-Known Member

I didn't like the specs, prefer older anyway, but not too old. The Rotel 02 to 05 amps are what I've really got my eye on, they seem nicer than the modern £500 A11 Tribute, which apart from anything else has a phono stage that will be overloaded by the current favorite cart, a Shure M44E with new original stylus, same with that Onkyo I think. Good find though, maybe I'm being too narrow minded but want to be sure.The Onkyo went for a good price £122 + £15 postage

RobGordon

Well-Known Member

I am finally getting around to doing this as I think I hear some rumble/hum when the stylus is is contact with a record (possibly interferance from the DAC about a foot under the tonearm). The spindle turns smoothly and feels nicely damped, but there is no vertical motion. I could try more force pulling it upwards but want to careful. Have not tried adding oil yet as it seems the spindle should be lifted to do this. Any advice?The Hitachi bearing is a captive ball against thrust pad design and should be oiled the whole way down. As should the Technics, but the bottom of the SL-1200/etc. bearing housing is essentially a sieve. IOWs, the main bearings of a lot of DD decks are almost an afterthought.

The lack of any form of oil reservoir is why Technics specify such regular oiling, although their 'techniques' ignore the fact that there exists a spindle end down the bottom there. IOW, it is an oiled sleeve bearing that just happens to sit upon a thrust pad.

Keep in mind that putting a tiny drop of oil round the upper lip of the bearing well, Technics service style (post cleaning any ring of dirt away), isn't necessarily going to lube the whole works. I suggest you repeat working in a drop at a time, lifting/lowering and rotating the spindle each time to help each drop be drawn in, until such time as none will be accepted.

WARNING: Under no circumstances should you follow the instructions posted within the vinylengine thread entitled Hitachi Direct Drive Unitorque Motor Oiling.

There is a slight bit of dirt on the plate at the bottom of the spindle. I think isoproply alcohol on cotton buds would be suitable for removing it, then removing any alc. residue with clean, dry buds. Otherwise all looks in good condition.

I cannot find this sort of info anywhere else on the 'net. This forum is invaluable.

Craig B

Re:trophile

Hi Rob,

I've just had a closer look and it does indeed appear that oiling the motor bearing is going to take somewhat more effort that simply placing a drop or two of lubricant at the base of the spindle. The motor will need be unscrewed from the plinth from below and the top motor cover will have to come off, in order to lift the spindle/rotor assembly up out of the bearing well.

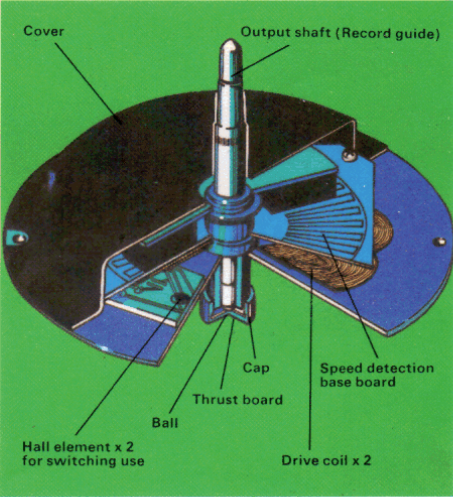

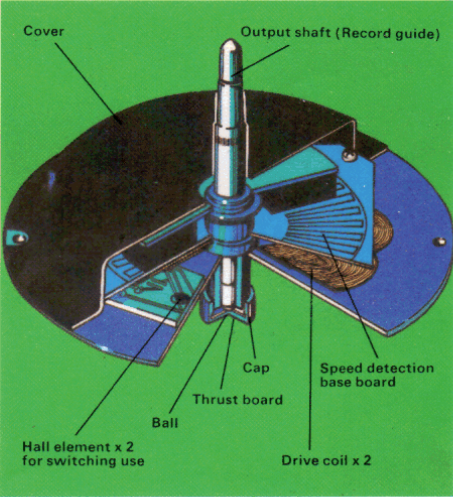

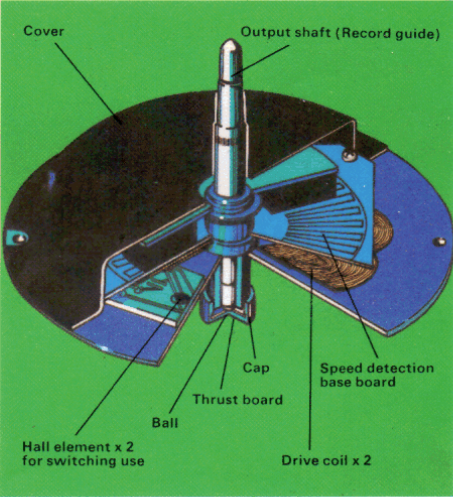

In the exploded diagram below, you'll notice a round fitting (just below 'Magnet (8-pole) and above 'Speed control' PCB) that attaches 'Rotor' and 'Magnet 8-pole' to the 'Output shaft (Record guide), aka the bearing spindle. As these are rotating parts they will be solidly attached to the spindle and present a barrier to oiling the bottom length of spindle that sits within the bearing well (i.e. the sintered bronze cylinder near the bottom between 'Yoke' and 'Ball' / 'Cap').

BTW. it will be magnetic attraction between magnet and coils that are resisting your efforts to test for vertical play. With the motor cover off, it should take a good tug upwards to release the spindle/rotor assembly.

Alternatively, you could try placing the deck upside down and attempt to unscrew the bearing cap, however, I would advise against any brute force methods, such as, the use of channel lock pliars, in situ, as employed by the fellow over on vinylengine.

Craig

I've just had a closer look and it does indeed appear that oiling the motor bearing is going to take somewhat more effort that simply placing a drop or two of lubricant at the base of the spindle. The motor will need be unscrewed from the plinth from below and the top motor cover will have to come off, in order to lift the spindle/rotor assembly up out of the bearing well.

In the exploded diagram below, you'll notice a round fitting (just below 'Magnet (8-pole) and above 'Speed control' PCB) that attaches 'Rotor' and 'Magnet 8-pole' to the 'Output shaft (Record guide), aka the bearing spindle. As these are rotating parts they will be solidly attached to the spindle and present a barrier to oiling the bottom length of spindle that sits within the bearing well (i.e. the sintered bronze cylinder near the bottom between 'Yoke' and 'Ball' / 'Cap').

BTW. it will be magnetic attraction between magnet and coils that are resisting your efforts to test for vertical play. With the motor cover off, it should take a good tug upwards to release the spindle/rotor assembly.

Alternatively, you could try placing the deck upside down and attempt to unscrew the bearing cap, however, I would advise against any brute force methods, such as, the use of channel lock pliars, in situ, as employed by the fellow over on vinylengine.

Craig

RobGordon

Well-Known Member

Aha, I think I understand, no idea where you got those diagrams from (don't think they are in the service manual) but this is, again, very useful. I will have a go at removing the motor cover and seeing about the rest when I'm feeling brave and have the time to be patient with this. Despite my lack of DIY experience I think this might just be within my capabilities. Many thanks once again.Hi Rob,

I've just had a closer look and it does indeed appear that oiling the motor bearing is going to take somewhat more effort that simply placing a drop or two of lubricant at the base of the spindle. The motor will need be unscrewed from the plinth from below and the top motor cover will have to come off, in order to lift the spindle/rotor assembly up out of the bearing well.

In the exploded diagram below, you'll notice a round fitting (just below 'Magnet (8-pole) and above 'Speed control' PCB) that attaches 'Rotor' and 'Magnet 8-pole' to the 'Output shaft (Record guide), aka the bearing spindle. As these are rotating parts they will be solidly attached to the spindle and present a barrier to oiling the bottom length of spindle that sits within the bearing well (i.e. the sintered bronze cylinder near the bottom between 'Yoke' and 'Ball' / 'Cap').

BTW. it will be magnetic attraction between magnet and coils that are resisting your efforts to test for vertical play. With the motor cover off, it should take a good tug upwards to release the spindle/rotor assembly.

Alternatively, you could try placing the deck upside down and attempt to unscrew the bearing cap, however, I would advise against any brute force methods, such as, the use of channel lock pliars, in situ, as employed by the fellow over on vinylengine.

Craig

Craig B

Re:trophile

The exploded diagram was cropped from a scan of an Hitachi PS-58 (the full-auto model) ad from the '70s, and the cutaway of the motor was cropped from a scan of a flyer from the same period. I think the service manual cutaway of the motor is the same as the colour one above.Aha, I think I understand, no idea where you got those diagrams from (don't think they are in the service manual) but this is, again, very useful. I will have a go at removing the motor cover and seeing about the rest when I'm feeling brave and have the time to be patient with this. Despite my lack of DIY experience I think this might just be within my capabilities. Many thanks once again.

I've not had this particular HItachi model apart, however, I'd be the first to agree that patience is a bodger's virtue.

It appears that on this series of wooden plinth models, the motor and semi-auto mechanism are mounted on a metal plate; a good thing when the intention is not only to put it all back together again, but also to have the spindle end up at a perfect 90º to the plinth. A good rule of thumb here is to not over-tighten anything.

Despite the semi-auto mech appearing to interface with the motor, these are separate and should present no hindrance/extra work.

Looks like you'll be wanting a small nut driver. Then again, it wouldn't hurt to give the bearing end cap a try by hand, in situ; however, I suspect these would have been treated with thread locker.

seeformiles

pfm Member

A bit off topic here, but has anyone heard the new Wharfedale Diamond 12 series speakers (12.1, 12.2)?They seem to be getting favorable reviews.

RobGordon

Well-Known Member

OK, I admit defeat. I think at some point I will be printing off all this and showing it to the local repair guy (he did an excellent job of repairing a Technics SL-200 with busted auto-return). For now, the "rumble/hum" appears to just be a few knackered old records (heavily scratched, out of phase mono Pet Sounds from 1966 anyone?), there is no noise with others. The auto-return is a little shaky but does its job and the RPM app says the speed is on point. There's a big 0.16% wow and flutter but I think that's because it takes a while to get going (as explained in the manual) and the app measures over the first seconds. I cannot hear it in any case.The exploded diagram was cropped from a scan of an Hitachi PS-58 (the full-auto model) ad from the '70s, and the cutaway of the motor was cropped from a scan of a flyer from the same period. I think the service manual cutaway of the motor is the same as the colour one above.

I've not had this particular HItachi model apart, however, I'd be the first to agree that patience is a bodger's virtue.

It appears that on this series of wooden plinth models, the motor and semi-auto mechanism are mounted on a metal plate; a good thing when the intention is not only to put it all back together again, but also to have the spindle end up at a perfect 90º to the plinth. A good rule of thumb here is to not over-tighten anything.

Despite the semi-auto mech appearing to interface with the motor, these are separate and should present no hindrance/extra work.

Looks like you'll be wanting a small nut driver. Then again, it wouldn't hurt to give the bearing end cap a try by hand, in situ; however, I suspect these would have been treated with thread locker.

I would almost certainly break something I think or be unable to put it all back together. Appreciate the lengths you've gone to here though. If magazine ads were showing the internals like that, this must have been considered something special. Certainly the best sounding turntable I've owned over the last year (out of something like ten, all vintage) since giving away my Vestax PDX 200 MkII, and it beats the Vestax too I think. It's beautiful too.

Thanks again, this will almost certainly come in useful down the line.

Craig B

Re:trophile

It sounds as though it is working well, Rob.

The way I read the motor service manual, Hitachi set out to maintain constant torque over über-fast start-up time. Regardless, the start to stable speed spec is circa 3.5sec, (2.5sec to 33.33rpm, plus 0.3% overshoot and 0.2% undershoot for a sec, or so).

Meanwhile, Matshushita/Panasonic/Technics were in a race with themselves to get up to stable speed within a quarter of a revolution. If only they'd known about slip-mats back then!

Also, as you mentioned that the spindle 'turns smoothly and feels nicely damped', it certainly can't be bone dry down there.

Enjoy!

The way I read the motor service manual, Hitachi set out to maintain constant torque over über-fast start-up time. Regardless, the start to stable speed spec is circa 3.5sec, (2.5sec to 33.33rpm, plus 0.3% overshoot and 0.2% undershoot for a sec, or so).

Meanwhile, Matshushita/Panasonic/Technics were in a race with themselves to get up to stable speed within a quarter of a revolution. If only they'd known about slip-mats back then!

Also, as you mentioned that the spindle 'turns smoothly and feels nicely damped', it certainly can't be bone dry down there.

Enjoy!