john & Jake

Jake was smarter than me

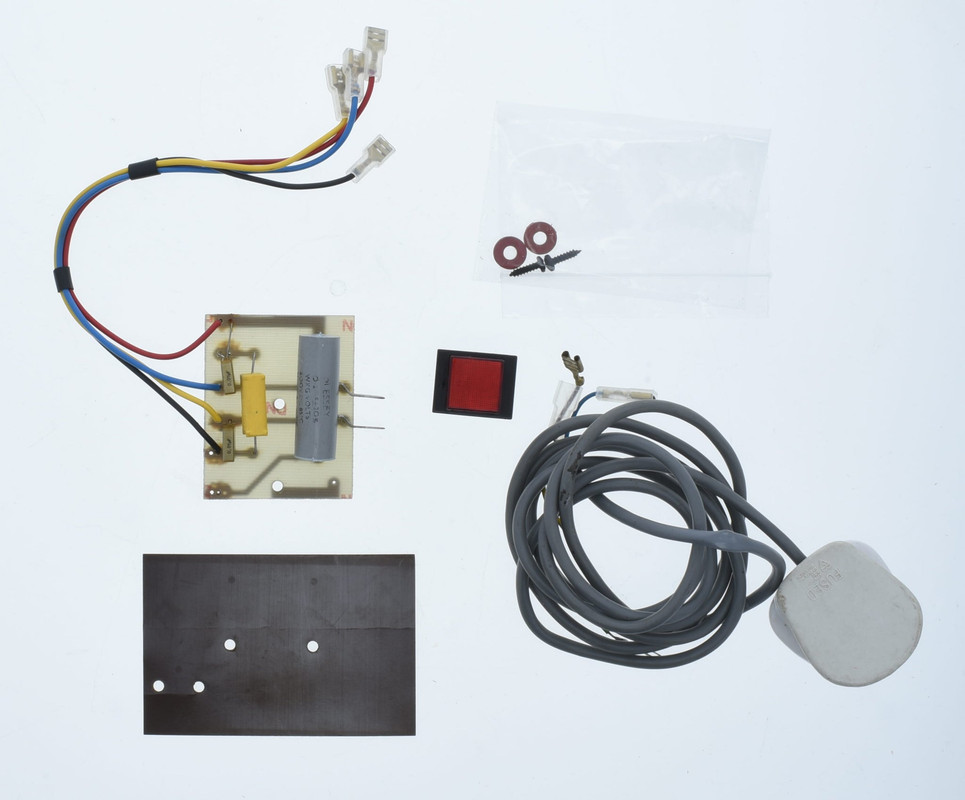

Final incarnation just waiting for power supply parts.

Much reduced mass using more air than foam.

1mm epoxy resin, foam,0.5mm carbon fibre sandwich.

6mm thick alloy bar embedded in the foam to directly couple the arm to spindle bearing.

Rega arm, Nagoaka MP200 cart

Much reduced mass using more air than foam.

1mm epoxy resin, foam,0.5mm carbon fibre sandwich.

6mm thick alloy bar embedded in the foam to directly couple the arm to spindle bearing.

Rega arm, Nagoaka MP200 cart