I've finally got an Audio Innovations P2. I'm one week in and enjoying it immensely.

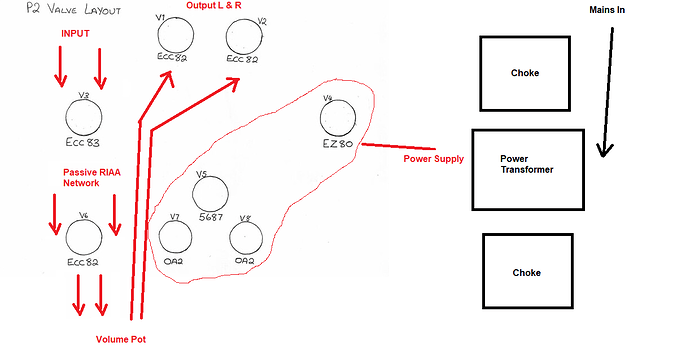

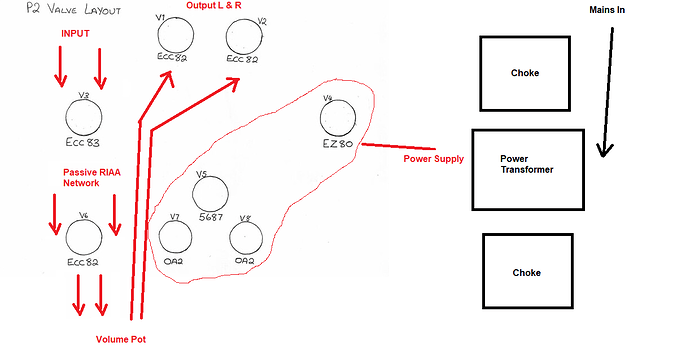

Now of course, I'm wondering about tube rolling and wondering exactly where I will get the best bang per buck, rolling the valves in the signal path? The valve layout in my P2 is:

My inclination is the v3 the ECC83 followed by the v4 ECC82 and then v1 & v2. Is this correct?If not what would you suggest?

Please suggest some reasonably priced options and possible reliable sources.

Sorry for the delay in posting on this thread. Been a bit busy.

I haven’t used the P2 since the first week or so I had it. Thanks for selling me it Steve. It’s in really great condition. Steve had a problem with hum and some of it was down to noisy trimmer pots but I think it was mostly from the T2 step up transformers, as with my S&B TX103 step ups hum is not a major problem.

I need to do some things to the P2 - adjustments etc, and want to upgrade some parts. I am using other phono stages at the moment.

I looked into the P2 a lot and have identified some issues. Guy Sergeant (who designed it) of Puresound told me that one of the three pairs of Jensen coupling caps were changed in value from the original spec of 0.22 uF to either 0.071, 0.068 uF(or 0.047 uF in some examples), as the filtering was too low in frequency and not needed. I went through the maths with some kind assistance from Simon Shilton (of SJS Electroacoustics). In my particular P2 the wrong set of coupling caps appears to have been changed in value (the second set in the 2nd stage has been changed in value instead of the first set/first stage). With the second set changed to 0.071 uF instead of 0.22 uF, the resultant high pass filter in that second stage has a -3dB point of 23 Hz, which is too high. This can give an issue for getting enough bass extension.

Also, If the power amp you use has an input impedance below 100 K ohms, having a 0.22 uF cap on the third stage (the output stage) won’t be high enough in value, also rolling off the bass further. If that cap value is changed to 0.47 uF minimum (or preferably 1uF or higher), the P2 would be more compatible with a wider range of preamps, power amps and integrateds with somewhat lower input impedance.

I was having issues with bass extension, and am sure these issues are the reason why.I had another P2 in the past, 15 years ago, and had the same bass extension issue. It was the main reason I sold it on.

So I intend to soon swap the 1st and 2nd set of coupling caps around so that 0.071 uF caps are in the first stage, and 0.22 uF caps are in the second stage. In the first stage the -3dB point with 0.071 uF caps is around 3 Hz, which is still plenty low enough. With 0.22 uF value it was about 1 Hz!

Changing the second stage coupling caps to 0.22 uF gives a -3dB point of 7.3 Hz (instead of 23 Hz) which Simon Shilton told me looked “about right”. Pic here of the proposed swap.

https://i.postimg.cc/5yR2ySzN/62-DF0-C10-4-F75-4-E6-F-9-D83-BACE5-C073257.jpg

Guys original circuit diagram shows that the cap value change is supposed to be in the first stage, not the second stage.

https://postimg.cc/cv0qDF1Z

The other thing I want to do is raise the coupling caps on the output to 0.47 uF or higher as mentioned above. I’ll have to buy some new caps for that. The problem is getting good quality PIO or Copper foil caps that will fit (as there isn’t much space). Standard metallized polypropylenes will definitely fit as the size is a lot smaller for a given value, but would be a downgrade. Caps I’ve found that are a perfect fit are Jupiter copper foil and wax 0.47 uF 400 V caps. Pricey though (about £150 for a pair).

Instead of buying a load of pricey tubes I suggest to spend some money on some basic maintenance and parts upgrades first. All the electrolytics in the P2 are now 30 years old and should all be replaced. It’s not expensive. You could just go for big standard ones or slightly better ones - such as various Nichicon Caps for about £40 total cost. These are what I intend to get. A more pricey option is Mundorf HV or Audio note basic electrolytics.

This is the most important maintenance to do.

If you fancy some small upgrades too for a reasonable price, what I plan to also do is this. Change the RIAA standard polystyrene caps for either copper foil polystyrenes (if i can find any such as Nobles (suggest by Guy)). Simon suggested Amtrans AMCH instead which are more readily available. Should be a nice upgrade. - need to be very spot with values though as the Amtrans are 5% tolerance. They need to be measured with an accurate capacitance meter.

I want to also change some of the stock metal film resistors to tantalums or (if on more or a budget) to 2W Kiwame Carbon films. Changing the parallel 47K input resistors and 1 M ohm output resistors is a good start. Then the anode load resistors as a priority after that. (This is what Simon suggested)

Change the wire wound resistors in the PSU section to 5W Kiwame Carbon films.

Change the standard cheap electrolytic cathode bypass caps (there are six of them: 2 for each signal tube) to either Elma Silmics or OS Cons (suggested by Guy). Very cheap to buy Silmics. Black gates are probably even better but discontinued and much harder to find.

This cost of the parts for this maintenance (changing the electrolytics) and some small upgrades is not expensive. £100 is so (unless using the tantalum resistors). If you can solder yourself this is a no brainier IMO before changing any tubes.

For further bigger upgrades I’ve been advised that the original Jensen coupling caps can definitely be improved upon. Also sometimes older PIOs can leak too

The Jensens PIO caps were good choice for good price/performance ratio at the time but they maybe aren’t so clear sounding by modern standards and can apparently sound a bit fuzzy. Simon advised me to go for Dueland JDM copper foils, Jupiter copper foil in Paper and wax, Audyn copper max, or Hovland musicaps (but they are discontinued). I’ve researched well into all these caps and only ones that will definitely fit easily into the P2 are the Jupiter caps in the 400V version, which are a bit pricey but perfect sizes. The Duelunds might possibly fit in the first and second stages with some work and apparently have as good if not better performance than the Jupiters.

I’m going to do mine in stages, - change the electrolytics, swap those Jensen caps around, change the pair of output caps (likely to the Jupiters in 0.47 or maybe even 1 uF if there is a way to somehow squeeze them in), and upgrade all the coupling caps

You might want to replace the 22K trimmer pots in the regulation stage too if they are noisy. I have some new ones but not done it yet. Also it’s best to set up the voltage of the value regulation system using the trimmer pots and a multimeter. I have some instructions written by Kevin from Definitive Audio. You are looking to get 4.5 V across two particular resistors by adjusting the 22K trimmer pots. In my experience this works well and makes the sound more focused and tight.

Pics here

https://postimg.cc/ct4hfrGS

https://postimg.cc/ns4d9xft

As for tube upgrades, one of the tubes could be a Mullard but I found having them all as Mullards made the sound too smooth and dark. I’d recommend other vintage tubes like Brimars, Philips, Siemens or others people have recommended. Maybe a mix with one or two sets of the tubes Mullards. A single Mullard ECC82 (or military equivalent) with some light use for the second stage shouldn’t be too expensive. More pricey for the ecc83 in the first stage (the input tube). You might need to find lower noise tubes as in the P2 noiser tubes can be an issue, if you speakers are more sensitive ones. Guy said that it’s particularly important that the pair of ECC82s in the output stage are quiet. I have personally found you can get issues with noisy tubes in any of the signal positions. I used headphone a lot and they are higher sensitivity than most speakers, so a quiet noise fooor is important for me.

Recommend Mullards for the OA2s and a NOS rectifier. Maybe Mullard or Brimar etc.

Different brands of tubes in all three sets of the signal tubes (ECC83 and the three ECC82s) will affect the sound. I’m not totally sure if the tube(s) in one of the stages is supposed to affect the sound more than others but I find they all do to pretty much the same extent.

Like I say though, I’d concentrate on maintenance and a few basic upgrades first, and fixing the cap values if your second set of coupling caps is 0.071 or 0.068, or 0.047 uF. I’d check that first.

Hope this helps, and also for anyone else with a P2 that wants to overhaul it.