karma67

pfm Member

Sony TTS-8000 Bearing Upgrade.

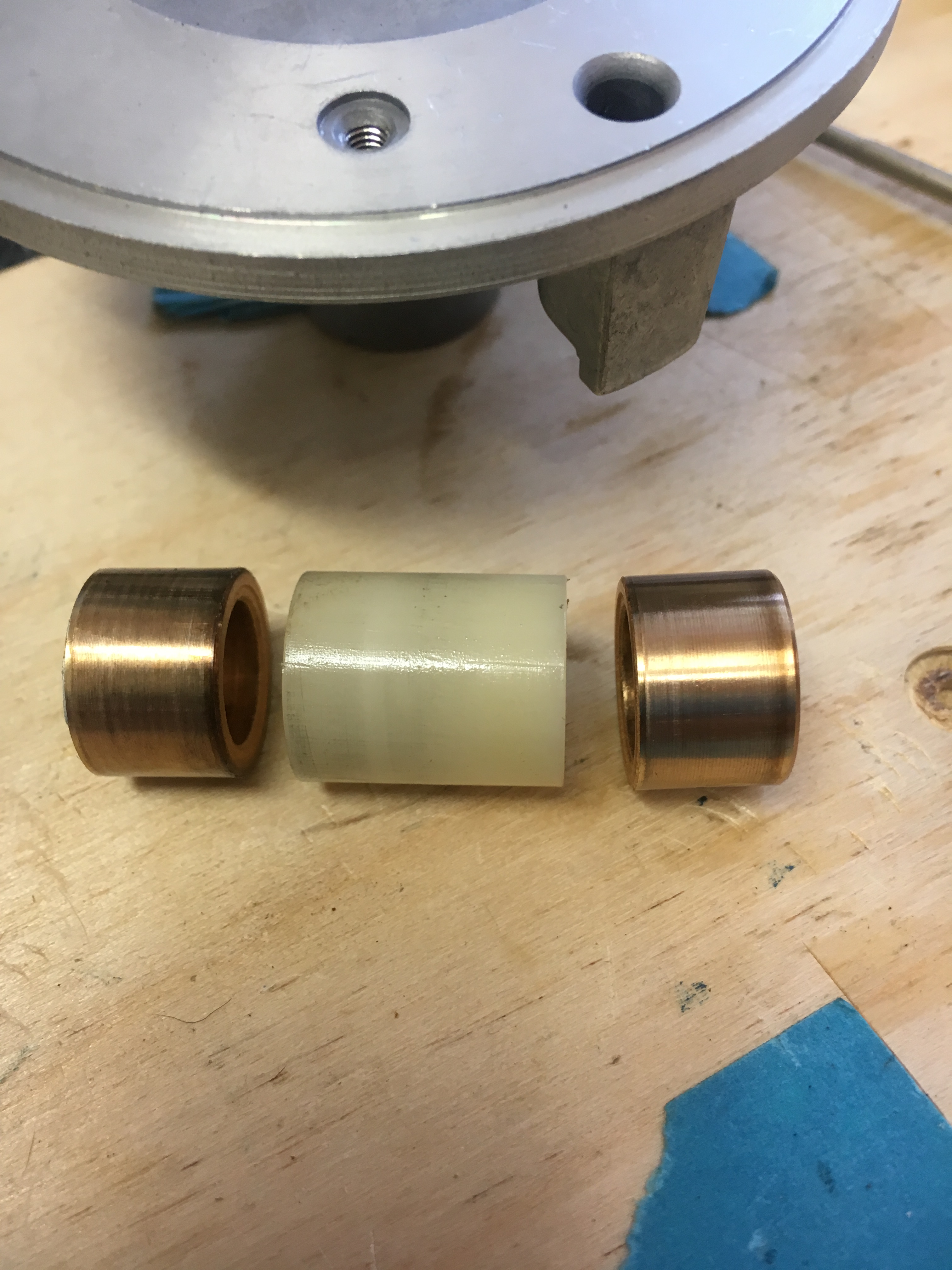

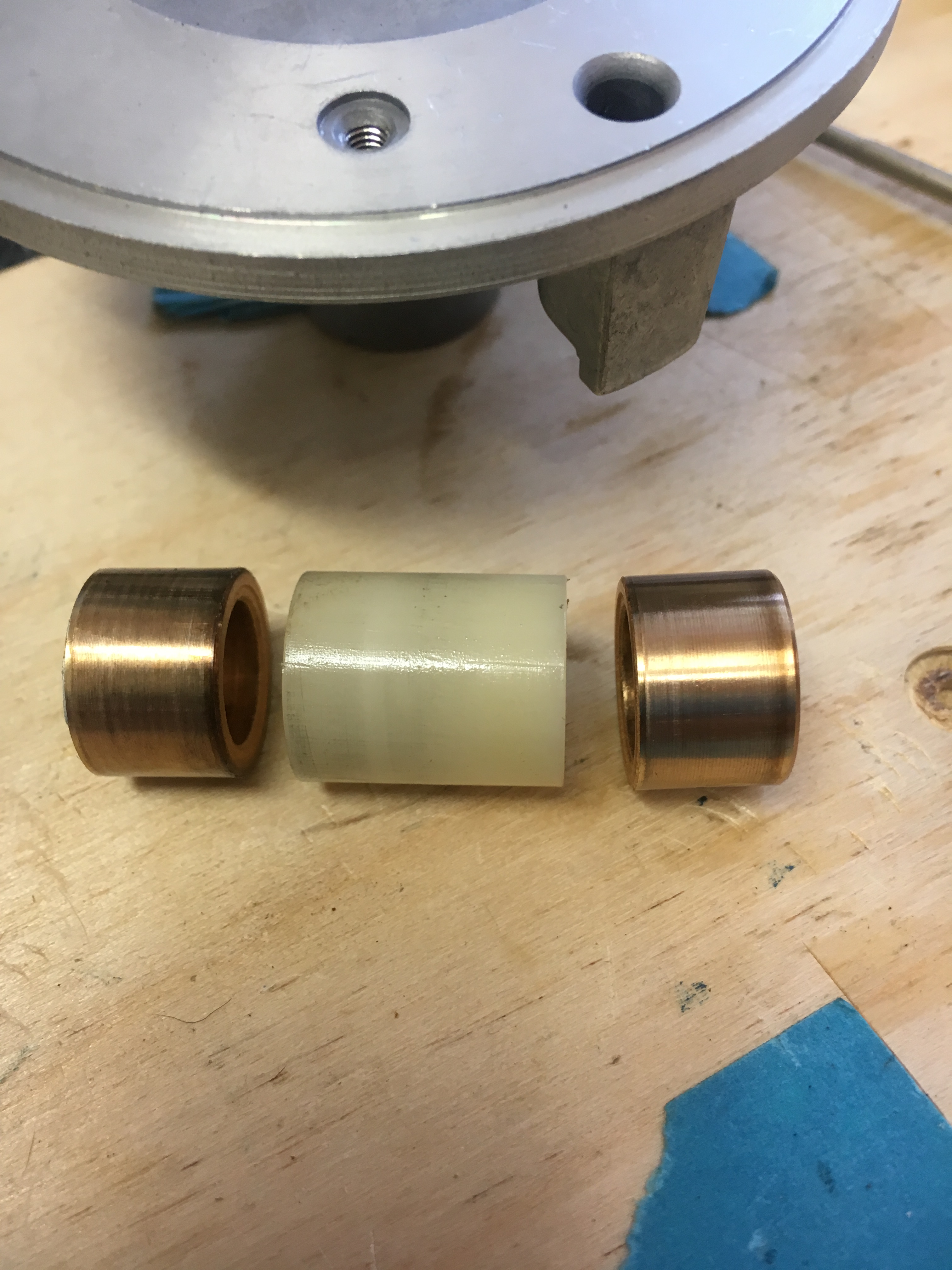

Sony originally used oilites/sintered bronze bearings in most of their turntables,the TTS-8000 is no exception.

2 oilites are used along with a nylon? spacer.

The merits of using Lignum Vitae for bearings are well documented, see here, https://www.google.com/search?client=firefox-b-d&q=lignum+vitae+bearings

I have heard Torlon bearings in the past and they greatly reduced any noise coming from the spindle/bearing surfaces,my train of thought was LV bearings could also be an

improvemnet.

So a few bids on ebay and i won a couple of old lawn bowling balls,i cut them up into 25mm square pieces and selected the best grain orientation to experiment with.

I turned and fitted 4 pairs before working out which working method produced the best tolerance, the spindle measures 10.98mm so an 11mm H7 reamer was used

to finish the bearings.

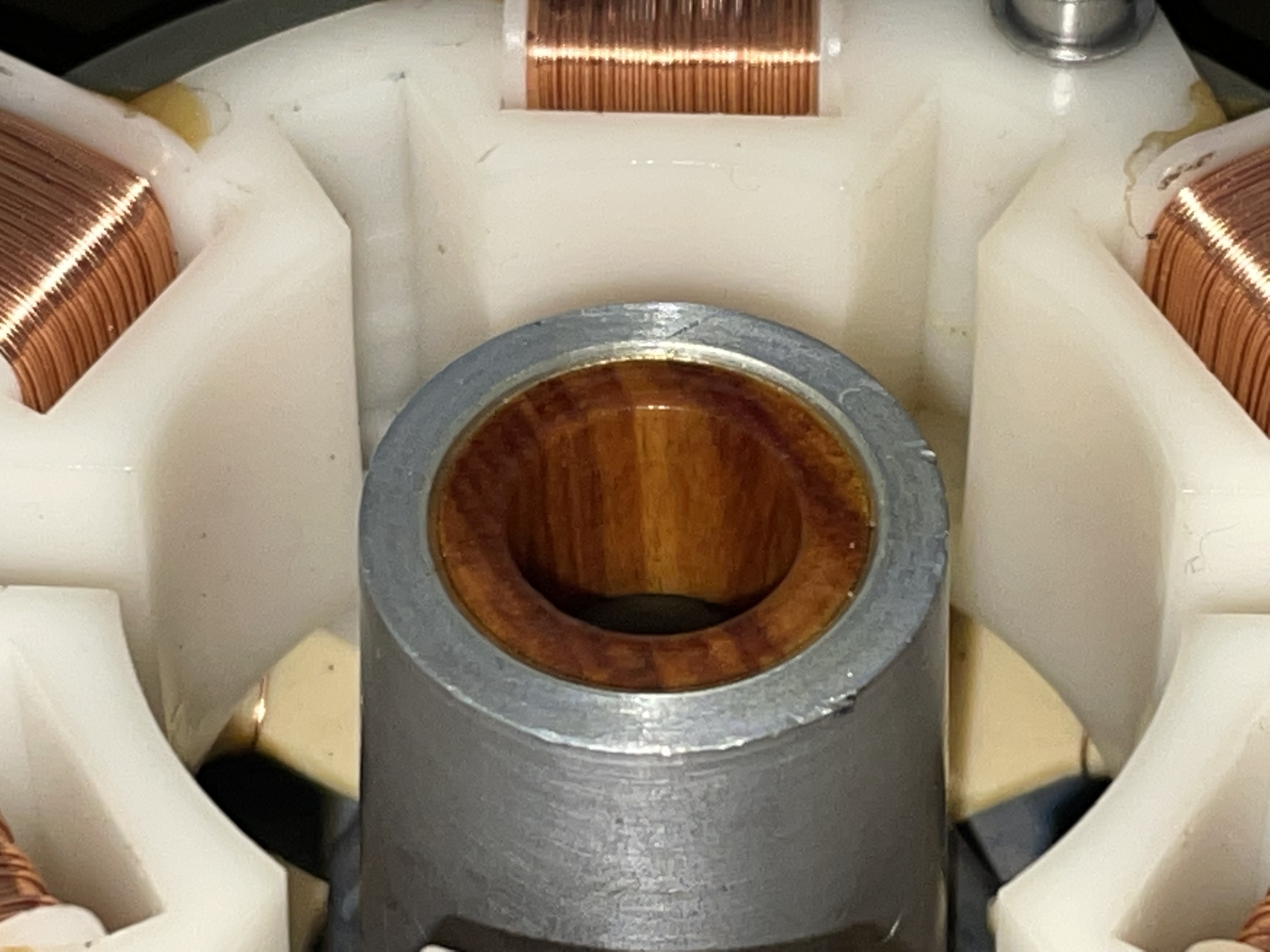

Bearing housing with bearing fitted and being trued up after initial drilling.

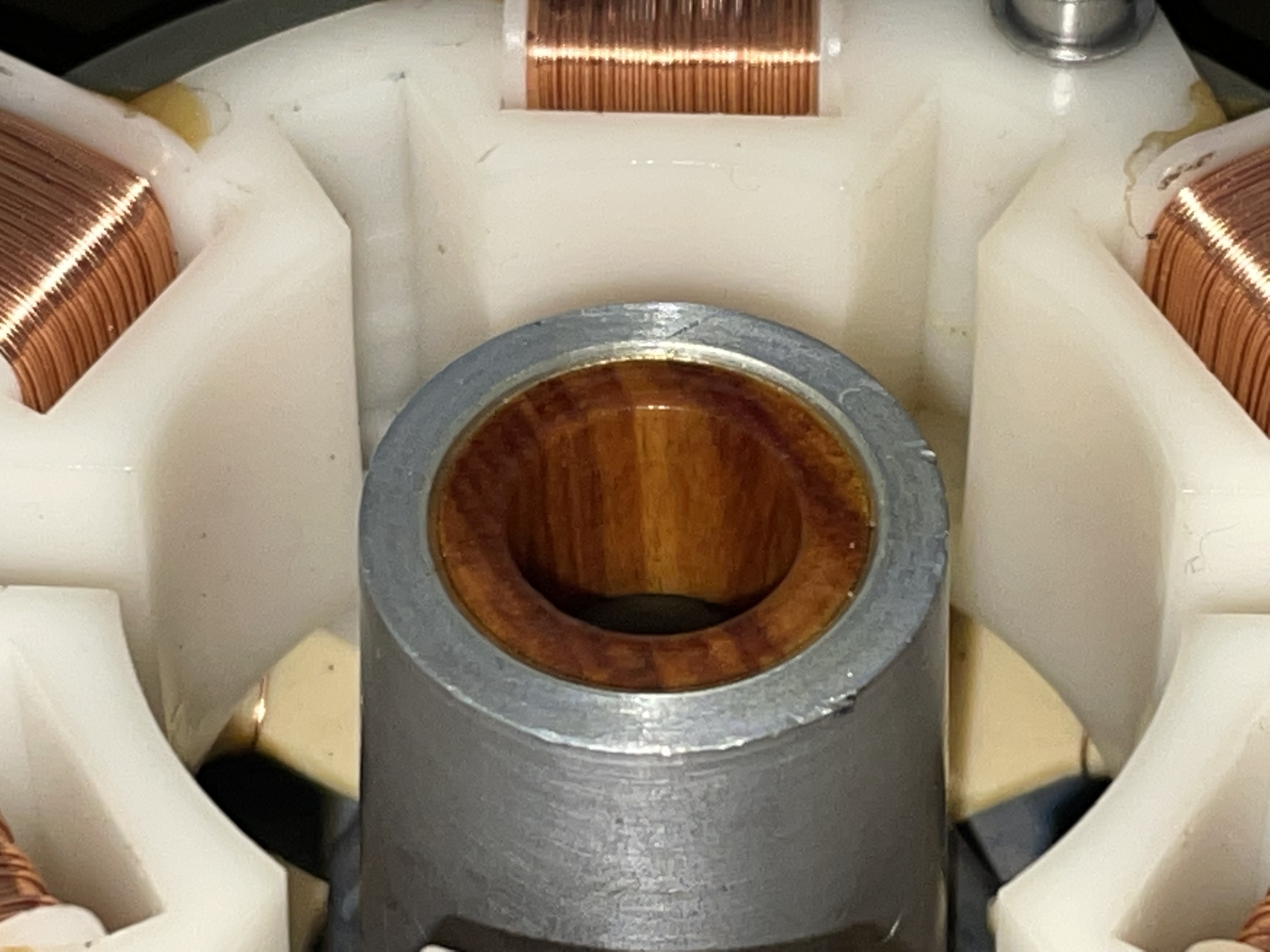

Top bearing fitted.

Whilst i was at it i also made a LV thrust pad to go with the bearings,the Sony one was Nylon.

The new LV one.

So thats it,job done,like the torlon bearings the LV ones have reduced the overall noise floor over the standard bronze bearings.The question left is which sounds better

Lignum Vitae or Torlon? My plan is to use the LV for a few months to bed in and then turn some torlon ones for comparison.

Sony originally used oilites/sintered bronze bearings in most of their turntables,the TTS-8000 is no exception.

2 oilites are used along with a nylon? spacer.

The merits of using Lignum Vitae for bearings are well documented, see here, https://www.google.com/search?client=firefox-b-d&q=lignum+vitae+bearings

I have heard Torlon bearings in the past and they greatly reduced any noise coming from the spindle/bearing surfaces,my train of thought was LV bearings could also be an

improvemnet.

So a few bids on ebay and i won a couple of old lawn bowling balls,i cut them up into 25mm square pieces and selected the best grain orientation to experiment with.

I turned and fitted 4 pairs before working out which working method produced the best tolerance, the spindle measures 10.98mm so an 11mm H7 reamer was used

to finish the bearings.

Bearing housing with bearing fitted and being trued up after initial drilling.

Top bearing fitted.

Whilst i was at it i also made a LV thrust pad to go with the bearings,the Sony one was Nylon.

The new LV one.

So thats it,job done,like the torlon bearings the LV ones have reduced the overall noise floor over the standard bronze bearings.The question left is which sounds better

Lignum Vitae or Torlon? My plan is to use the LV for a few months to bed in and then turn some torlon ones for comparison.