You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New cartridge time? - how do you know?

- Thread starter ossy

- Start date

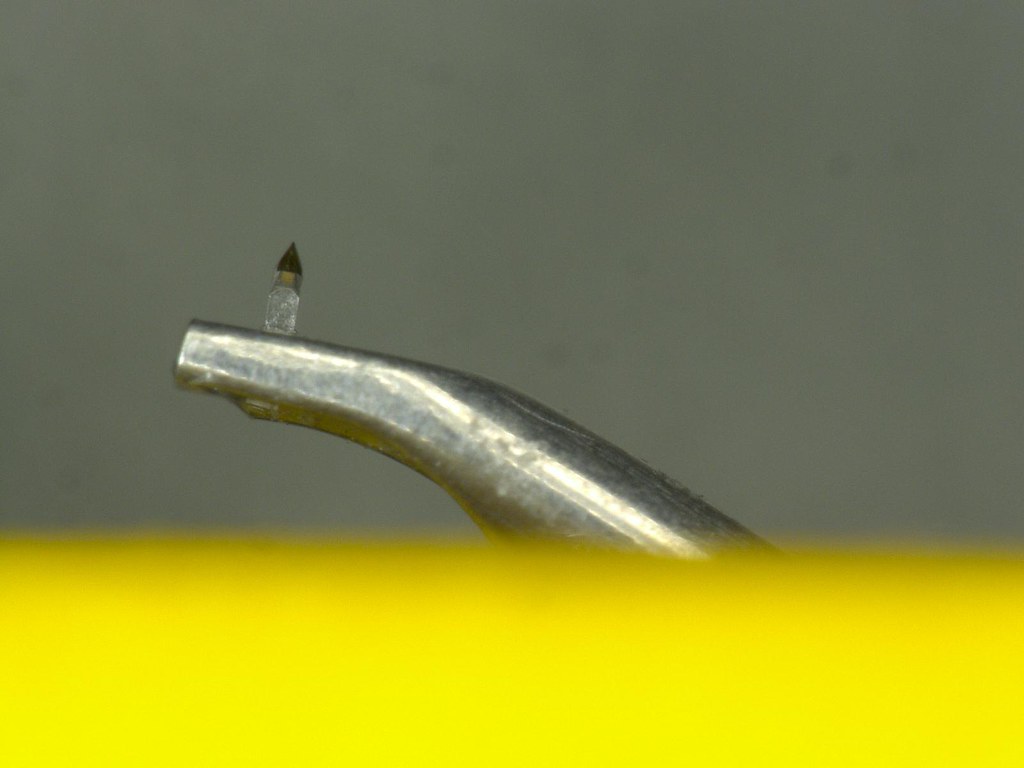

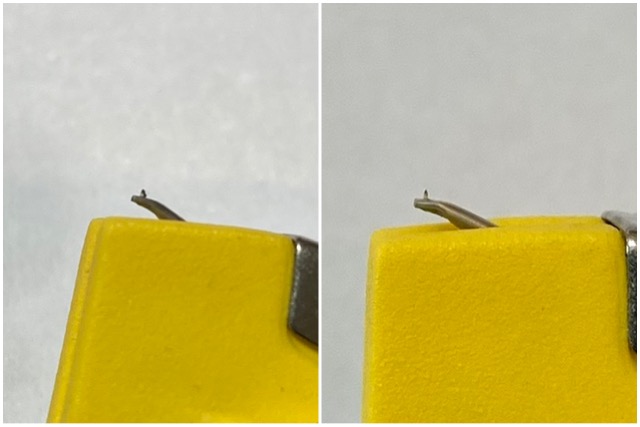

Looks like the tip is missing!

I’ve just borrowed a loupe, soaked the tip in alcohol and given it a good scrub - it now looks like the picture above!

Wow, was indeed dirty. Just need to put back and see if its still alive !!

sonddek

Trade: SUPATRAC

It is quite common to see this. The crud can really be almost welded on. I don't use fluids because I'm superstitious, but I do scrape all around the diamond with a sliver of 2500 grit paper (lost all the green stuff). If you hold the sliver (say 20mm x 5mm) at one end and scrape with the other you can easily apply non-fatal pressure. I've done this with so many cartridges now and never damaged or removed a diamond. Often I've seen under the microscope great stubborn cakes of crud come off, and often the sound is entirely rejuvenated when I had all but given up on it.

My stylus-cleaning routine is inspect always, brush often, scrape when suspicious and follow up with jewellers putty.

My stylus-cleaning routine is inspect always, brush often, scrape when suspicious and follow up with jewellers putty.

Craig B

Re:trophile

There is no need to remove the cartridge in order to give the tip a good cleaning. What you need is a better brush, something like this from Pro-Ject, Ortofon , and numerous others.I’ve just borrowed a loupe, soaked the tip in alcohol and given it a good scrub - it now looks like the picture above!

Wow, was indeed dirty. Just need to put back and see if its still alive !!

Nagaoka or audio-technica stylus cleaning fluid is worth having on hand for the occasional über-cleaning, otherwise use the brush dry each record playing session, only dragging back to front whilst contacting the tip with barely enough pressure to deflect the cantilever. Best to leave the tonearm unclipped from its rest, or just sitting on the raised cueing platform, just in case.

Big Tabs

looking backwards, going forwards

Thanks everybody, as always, excellent advice. I’d been cleaning the stylus regularly but had no idea so much black gunk had built up.

You have now reached Level 2 of your journey.

well done

Craig B

Re:trophile

Nice exhumation.From this to this:

It’s amazing what you can accomplish with some single malt and a bri

Am guessing that Level 3 is cleaning your ears.

You have now reached Level 2 of your journey.

well done

Am guessing that Level 3 is cleaning your ears.

Big Tabs

looking backwards, going forwards

It’s amazing what you can accomplish with some single malt and a bri

Am guessing that Level 3 is cleaning your ears.

pardon?

I haven’t reached that level yet.

Craig B

Re:trophile

There's a new tool for that called 'Tvidler', but my GP always warned me never to stick anything smaller than my elbow in; claims a few drops of warm oil will soften all and let run out. I've always assumed he meant mineral oil rather than Shell Spirax 80W-90 hypoid gear lube; only I've a big bottle of the latter here for servicing Rega Planars that I'll never get through.Am guessing that Level 3 is cleaning your ears.

John

Rack’em Up!

I’ve always gotten between 2500-3000 hours from my Linn MC cartridges. I usually notice end of side distortion or vocal sibilance when they need replacing. I rotate between Asaka, Klyde and Troika. Currently enjoying the Asaka which has maybe 10 hours on it. I clean the stylus every three or four sides with Rodico which does a good job. Here’s a shot of the Rodico after several months.

Another good way is to put a hot water bottle on your pillow and lie sideways on it. Local heat makes wax run. Gravity does the rest.

Ah, so my granny was being helpful when she said 'Awaw an boil yer heed!'

John

Rack’em Up!

I have one of those too that I purchased to service a Rega 2. Have no idea what use it has now sitting on a shelf in my basement. The quantity I have is over a hundred times what I needed.There's a new tool for that called 'Tvidler', but my GP always warned me never to stick anything smaller than my elbow in; claims a few drops of warm oil will soften all and let run out. I've always assumed he meant mineral oil rather than Shell Spirax 80W-90 hypoid gear lube; only I've a big bottle of the latter here for servicing Rega Planars that I'll never get through.

Craig B

Re:trophile

So, you don't happen to have a bus or heavy duty truck with a non-synchronized manual transmission, then? Also recommended for service fill of all limited slip differentials in passenger cars and light trucks calling for SAE 80W-90 and API Service GL-5 specifications.I have one of those too that I purchased to service a Rega 2. Have no idea what use it has now sitting on a shelf in my basement. The quantity I have is over a hundred times what I needed.

Last edited: