chiily

PFM Special Builder

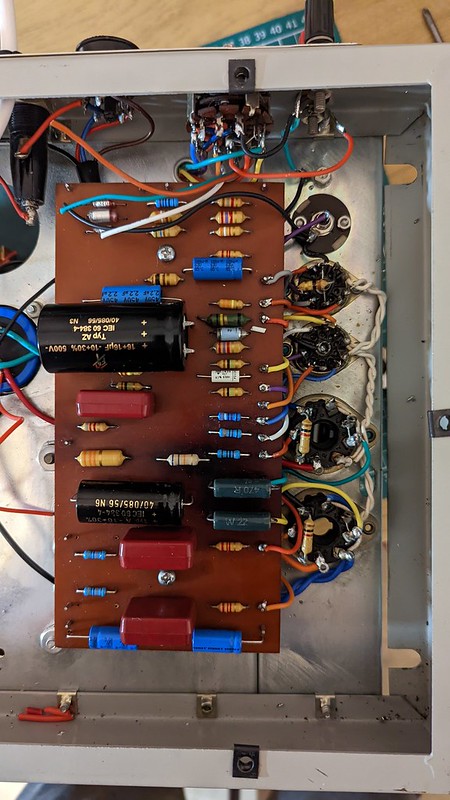

I have pictures of the wiring coming out of ears. My approach is going to be is to check each wire to see if it is "green" and replace if necessary one at a time. I'm not going to say remove all the wires and then re-wire, confusion and mis-wiring hides there

I have ten colour 22AWG and 24AWG wires on their way.

The "green" appears to be leaching out of the wire's plastic sheaf, and in a couple of places it is a liquid dripping on to other wires, green and goopy.

For me the STA15 is a step up in wiring complexity from the ST20. I am really enjoying it. The more I read the more I'm looking forward to enjoying music through it. Though the ST20 will take some beating now the NOS caps and new valves are bedding in. My new miniDSP Flex is wonderful too...

And of course the big question is which way around does the cover go, Radford label to the input output panel, or the other way around...

Gonna need a new label too...

I have ten colour 22AWG and 24AWG wires on their way.

The "green" appears to be leaching out of the wire's plastic sheaf, and in a couple of places it is a liquid dripping on to other wires, green and goopy.

For me the STA15 is a step up in wiring complexity from the ST20. I am really enjoying it. The more I read the more I'm looking forward to enjoying music through it. Though the ST20 will take some beating now the NOS caps and new valves are bedding in. My new miniDSP Flex is wonderful too...

And of course the big question is which way around does the cover go, Radford label to the input output panel, or the other way around...

Gonna need a new label too...

PXL_20220513_112352715~2

PXL_20220513_112352715~2 PXL_20220512_164629019

PXL_20220512_164629019 PXL_20220521_181201293

PXL_20220521_181201293 PXL_20220521_121715663

PXL_20220521_121715663 PXL_20220522_090330976

PXL_20220522_090330976 PXL_20220519_164303560~2

PXL_20220519_164303560~2 PXL_20220522_211831550~2

PXL_20220522_211831550~2