john.luckins

pfm Member

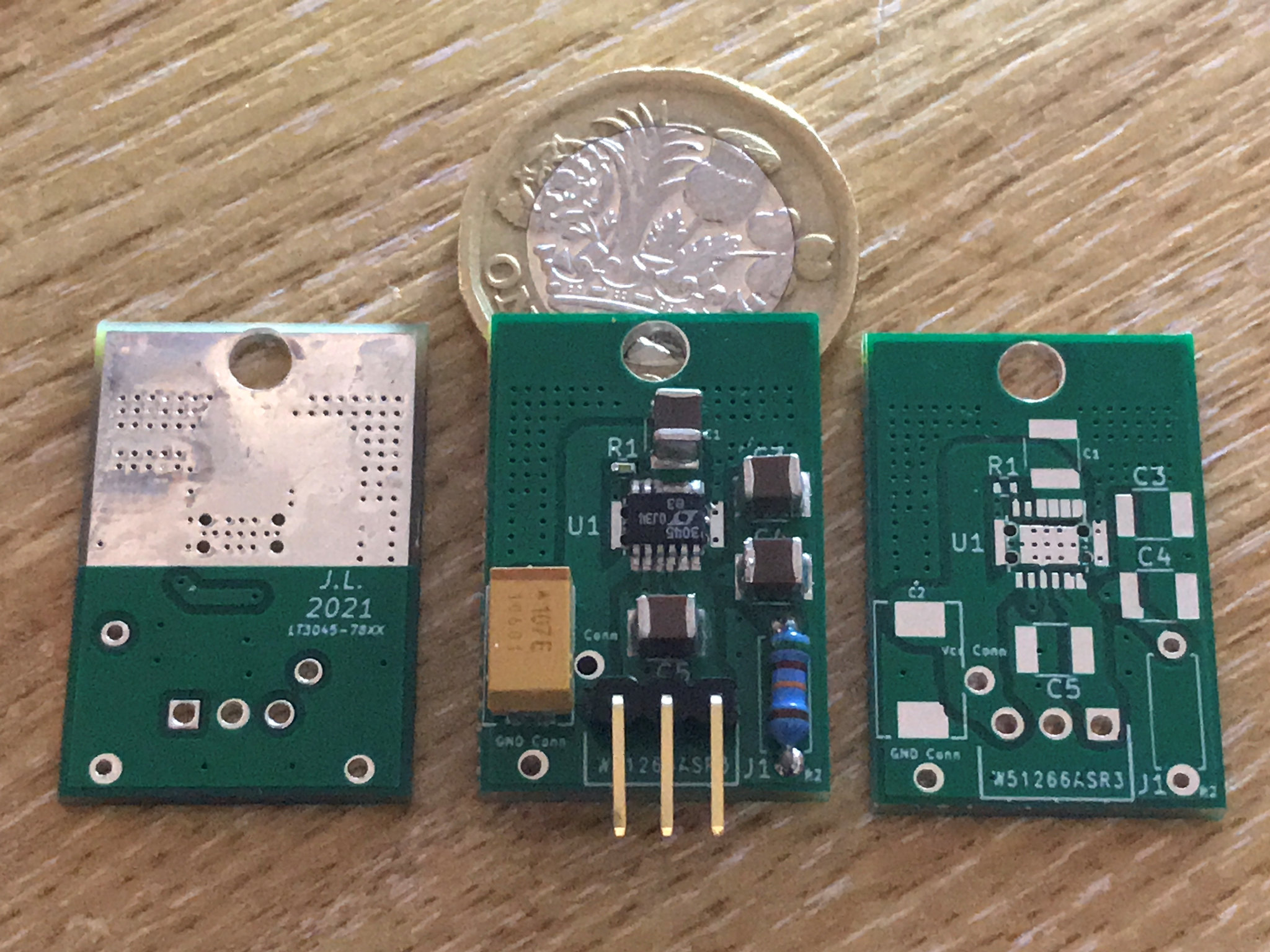

I thought I would share my first Kicad SMD board design. It is also only my second Kicad board, the first being thru hole.

https://flic.kr/p/2kPhsa7

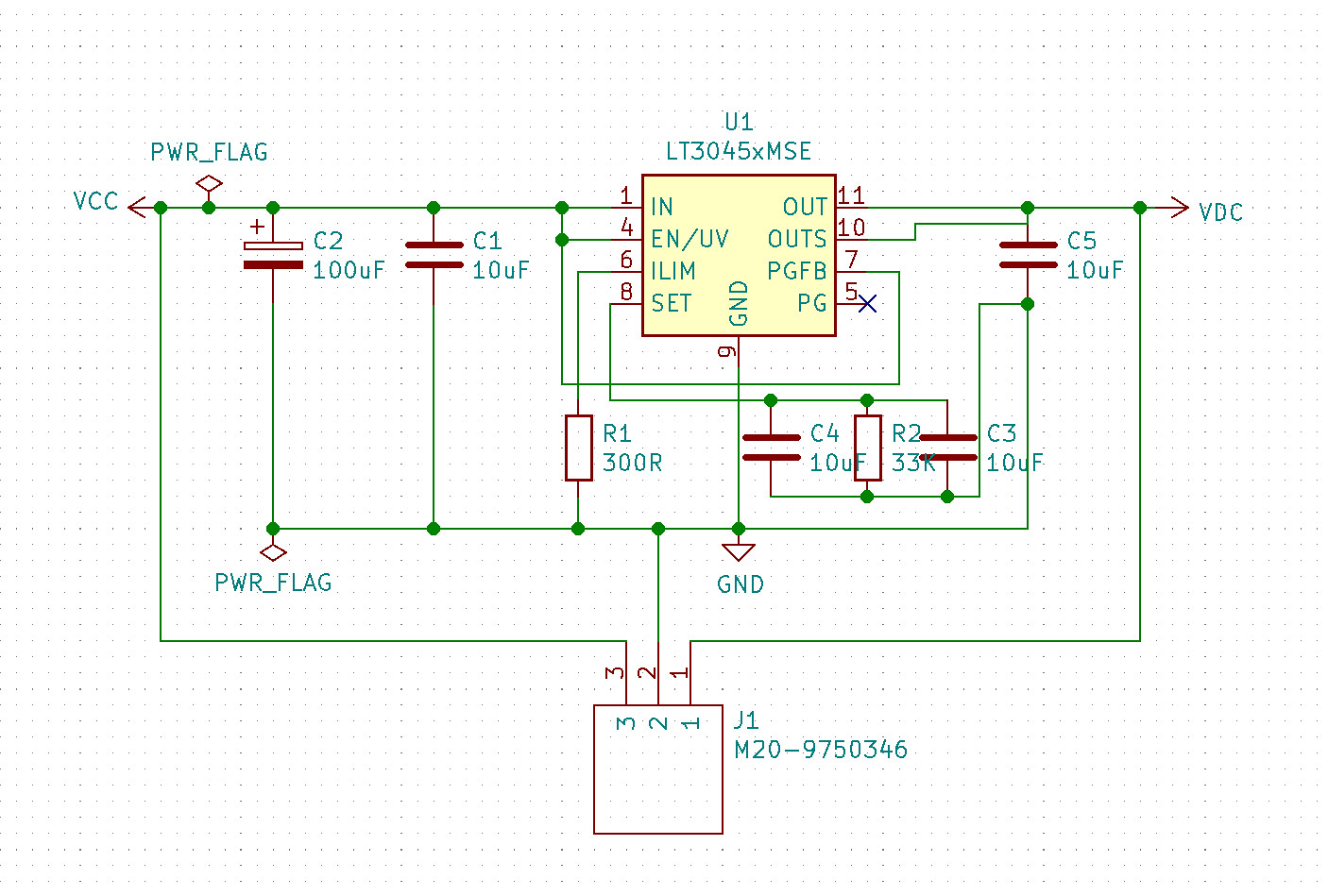

It is an adjustable LT3045 regulator with a 3 pin 78xx series pin out. It can source 500mA and I've just tested it with a heatsink dissipating 7.5 watts. It's output voltage is set by a hand soldered thru hole resistor and it has separate solder pads for 0v and Vin if you wanted to insert just its Ov and Vout pins in a circuit and run a separate supply feed to it, handy if you are modding kit with it. It has lower noise than the standard LT3045 circuit and uses higher voltage X7R capacitors as they hold their value better with voltage changes.

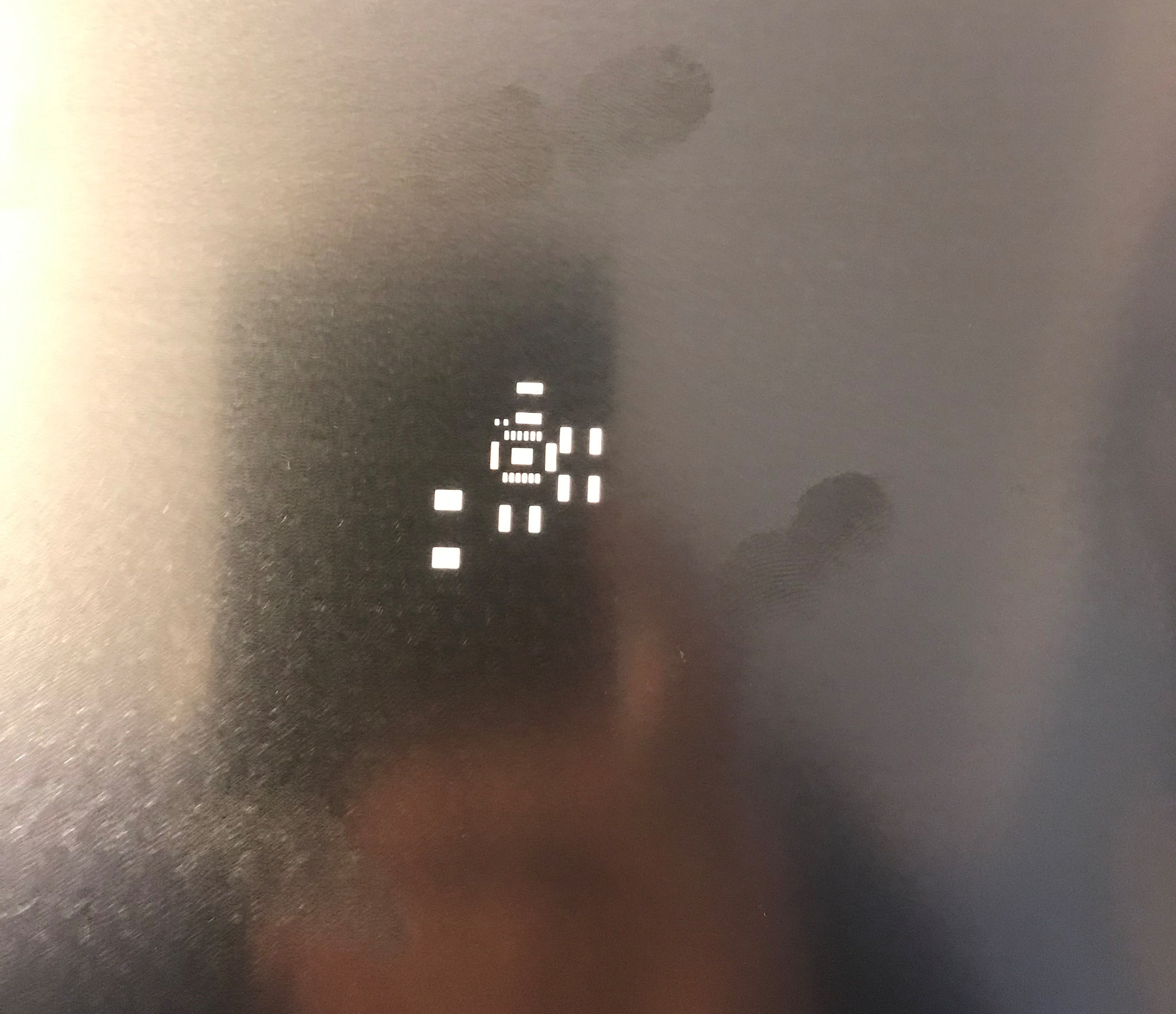

Now here's the interesting bit. It cost me only $1 extra to get 50 rather than 10 of these produced by PCBway, so I have more than I need. I also soldered the one in the photo in my kitchen oven this afternoon! It was much easier than I had expected, perhaps because of the leaded solder. The only special tool used was a £10 oven thermometer. Even the underside of the LT3045 soldered properly to the heatsink.

Over the next few weeks I'll be completing and checking some more of these and if things go well I'll test the water here for a group buy. I'm not trying to make money on these so we are looking at around £10-£12 fully populated (apart from the setting resistor). That's quite a saving on the ebay offerings of similar quality.

Maybe there will be no interest, but you never know....

John

https://flic.kr/p/2kPhsa7

It is an adjustable LT3045 regulator with a 3 pin 78xx series pin out. It can source 500mA and I've just tested it with a heatsink dissipating 7.5 watts. It's output voltage is set by a hand soldered thru hole resistor and it has separate solder pads for 0v and Vin if you wanted to insert just its Ov and Vout pins in a circuit and run a separate supply feed to it, handy if you are modding kit with it. It has lower noise than the standard LT3045 circuit and uses higher voltage X7R capacitors as they hold their value better with voltage changes.

Now here's the interesting bit. It cost me only $1 extra to get 50 rather than 10 of these produced by PCBway, so I have more than I need. I also soldered the one in the photo in my kitchen oven this afternoon! It was much easier than I had expected, perhaps because of the leaded solder. The only special tool used was a £10 oven thermometer. Even the underside of the LT3045 soldered properly to the heatsink.

Over the next few weeks I'll be completing and checking some more of these and if things go well I'll test the water here for a group buy. I'm not trying to make money on these so we are looking at around £10-£12 fully populated (apart from the setting resistor). That's quite a saving on the ebay offerings of similar quality.

Maybe there will be no interest, but you never know....

John