There is no excuse for incorrect mains wiring. As I understand it under current legislation only qualified electricians are allowed to install or modify mains supplies, so any landlord guilty of renting a dangerous house could be sued to hell and back and I’d take them for everything they had.

Agreed, however, the property in question had original fitment 'knob and tube' wiring which has long since been made illegal; so, not so much a case of incorrect wiring as it was unsafe to begin with starting well before WWI.

As Paul mentioned above, regs do vary widely around the world; I'd only add that it is often 'enforcement' that is the real problem. Over here in Ontario, for example, I am free to run a new spur to my hi-fi, however, the onus is on me to have a qualified electrician check my work and perform the final connection to the consumer unit. Plenty of DIY home improvement types ignore this and wire all straight into their electrical box. The missing link here, relative to your UK regs, is that it is our insurance companies that have become the unofficial enforcer of the Ontario Electrical Safety Code regs; with 'enforcement' generally coming in the form of a mailed out questionnaire/voluntary statement of compliance which a given homeowner might decided to fill out incorrectly should he/she need to buy time before being able to pay out the many thousands of dollars for a full electrical upgrade. IOW, admitting to 'knob and tube' equals insurance policy cancellation should the owner fail to get the property to be in compliance within a very short time period (30 days for new buyers, which is virtually impossible). I personally know of a half-dozen or so homeowners that lied to their insurance companies for years whilst saving up for the inevitable electrical upgrade; all the while quietly praying that they didn't have need to make a claim that might result in an insurance inspector coming round. Thankfully, such homes are becoming more of a rarity these days.

My point is given such faulty/illegal wiring you’d likely have blown a fuse/got a jolt/started a fire long before getting to cue your record deck as every other metal case component would be live too!

Over here ring mains are rare, with separate spurs to different floors/rooms and wall outlets vs. lights, etc. being the norm. As few as one or two outlets in an older rewired property could easily be on their own spur.

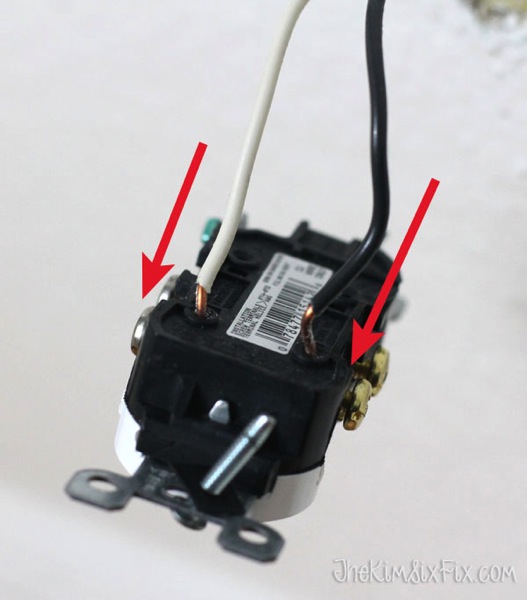

I strongly recommend everyone owns a mains testing plug such as

this one (countless similar alternatives available). Just plug it in and test the mains if you are moving anywhere new. I’ve had one for decades and thankfully never had anything but a safe reading anywhere I’ve lived.

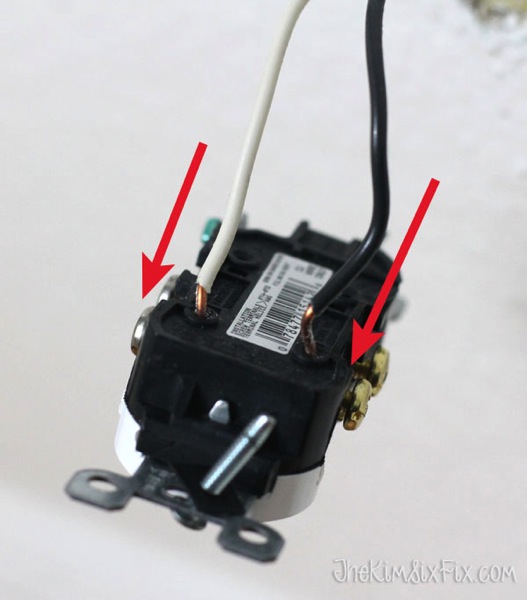

Before I even moved into my then new built house, I tested every outlet with one of these. All were fine wrt polarity and grounding, however, one was shorting as the contractors typically employ the nasty push through 'QuickWire' connections, rather than the more time consuming screw terminals (common garden variety electrical sockets generally have both types over here). I reconnected the lot of them via the screw terminals.

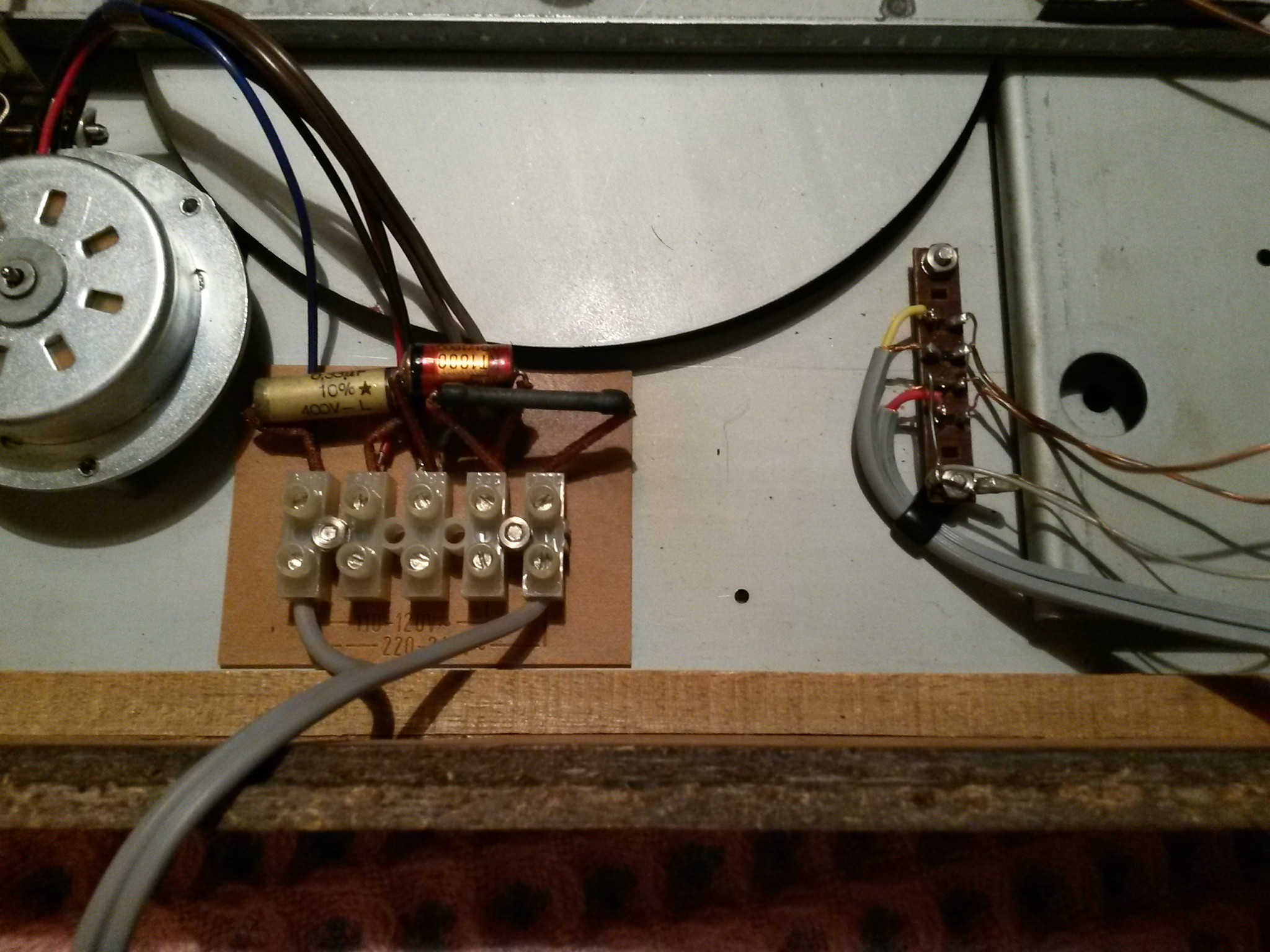

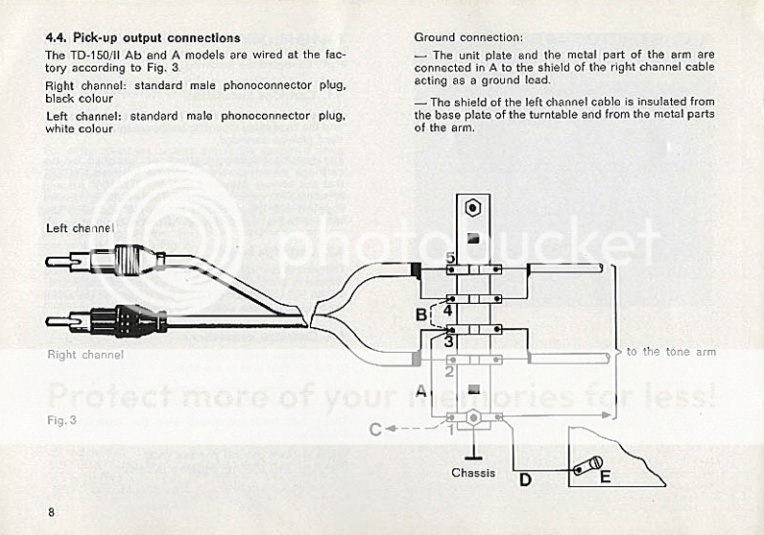

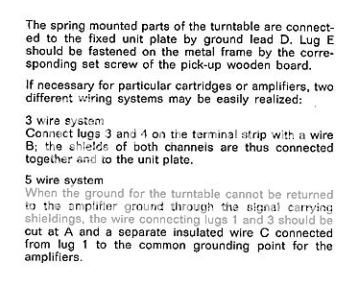

PS I’d argue the original Thorens wiring was dangerous as if one of the mains connectors came loose and touched the top-plate the only path to ground is via the very thin and flimsy arm-earth lead and we don’t know what phono stage is at the end of it, e.g. it may be powered by a 9v wall wart or whatever with no earth pin, and then you are gambling on finding earth via the amp’s RCA signal return. As such there is a chance the ring main circuit breaker wouldn’t trip and you have a potentially leathal fail condition even with perfectly legal and safe house wiring. The more I think about this one the more I am convinced I am right.

I wouldn't argue against this, however, I think your argument should include Ariston, Linn, and Systemdek, amongst others.