Fatmarley

"It appears my intelligence circuits have melted"

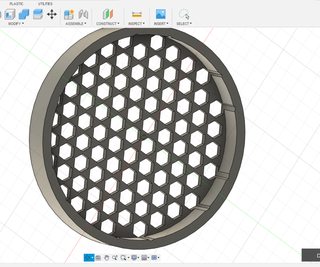

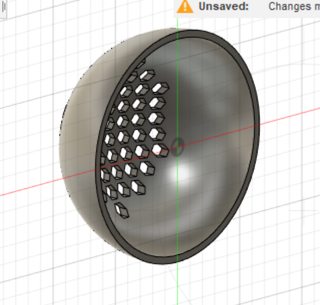

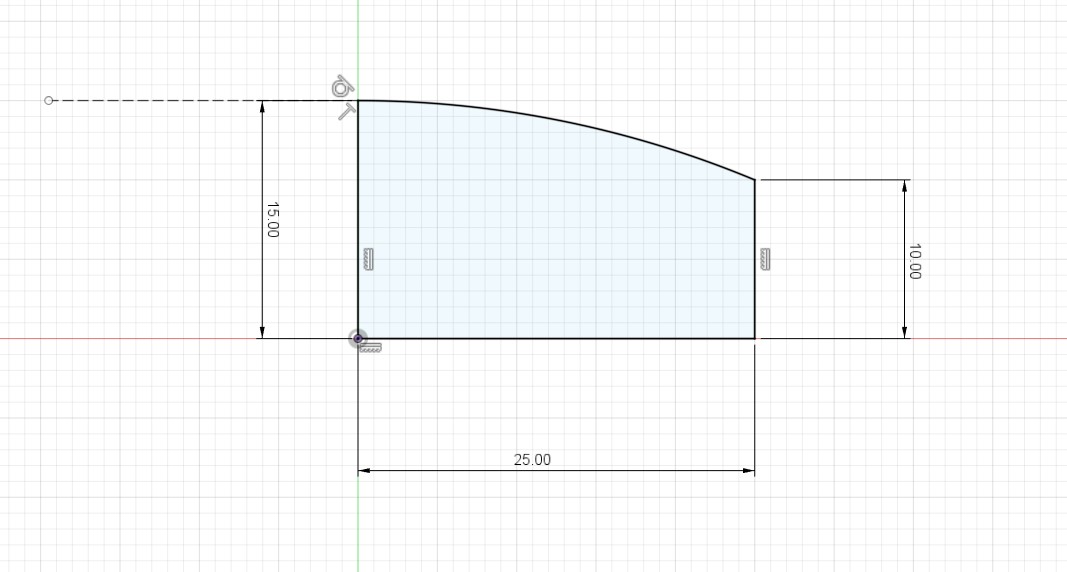

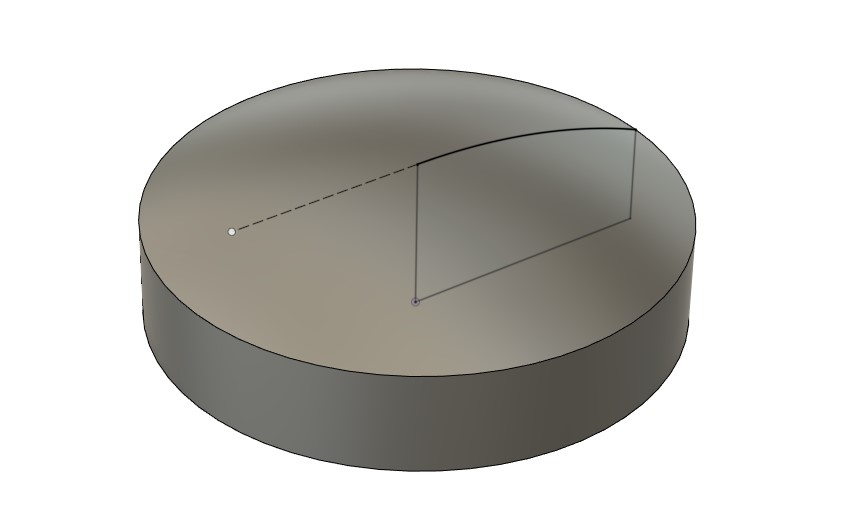

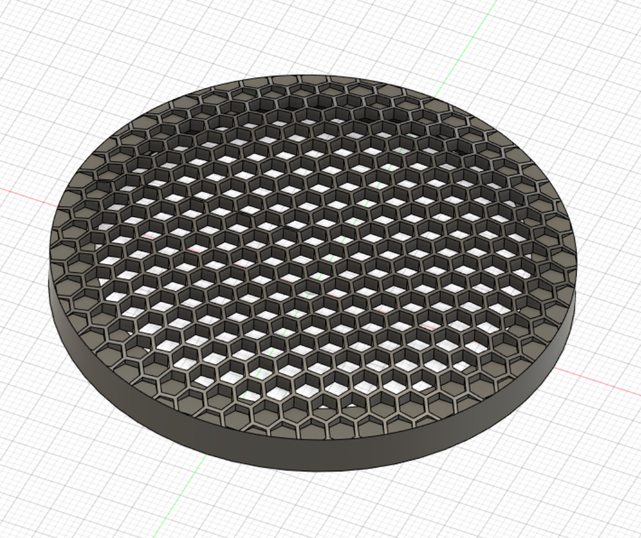

I've fitted some new tweeters in the car, and I'm worried about them being damaged because the two protection bars don't offer much protection to the soft dome.

Could someone 3d print a pair of grills for me? I'd be happy to pay for your time, materials and postage.

The tweeters are Vifa NE25VTS-04 - https://products.peerless-audio.com/transducer/120

Could someone 3d print a pair of grills for me? I'd be happy to pay for your time, materials and postage.

The tweeters are Vifa NE25VTS-04 - https://products.peerless-audio.com/transducer/120