Mike Hanson

Trying to understand...

I was able to get the parts for another NCC300 build from a friend who decided I was more eager than he was. I'm building it for another friend of mine, who's coming to visit in a few weeks. I'm hoping to have it done in time for him to take it home with him.

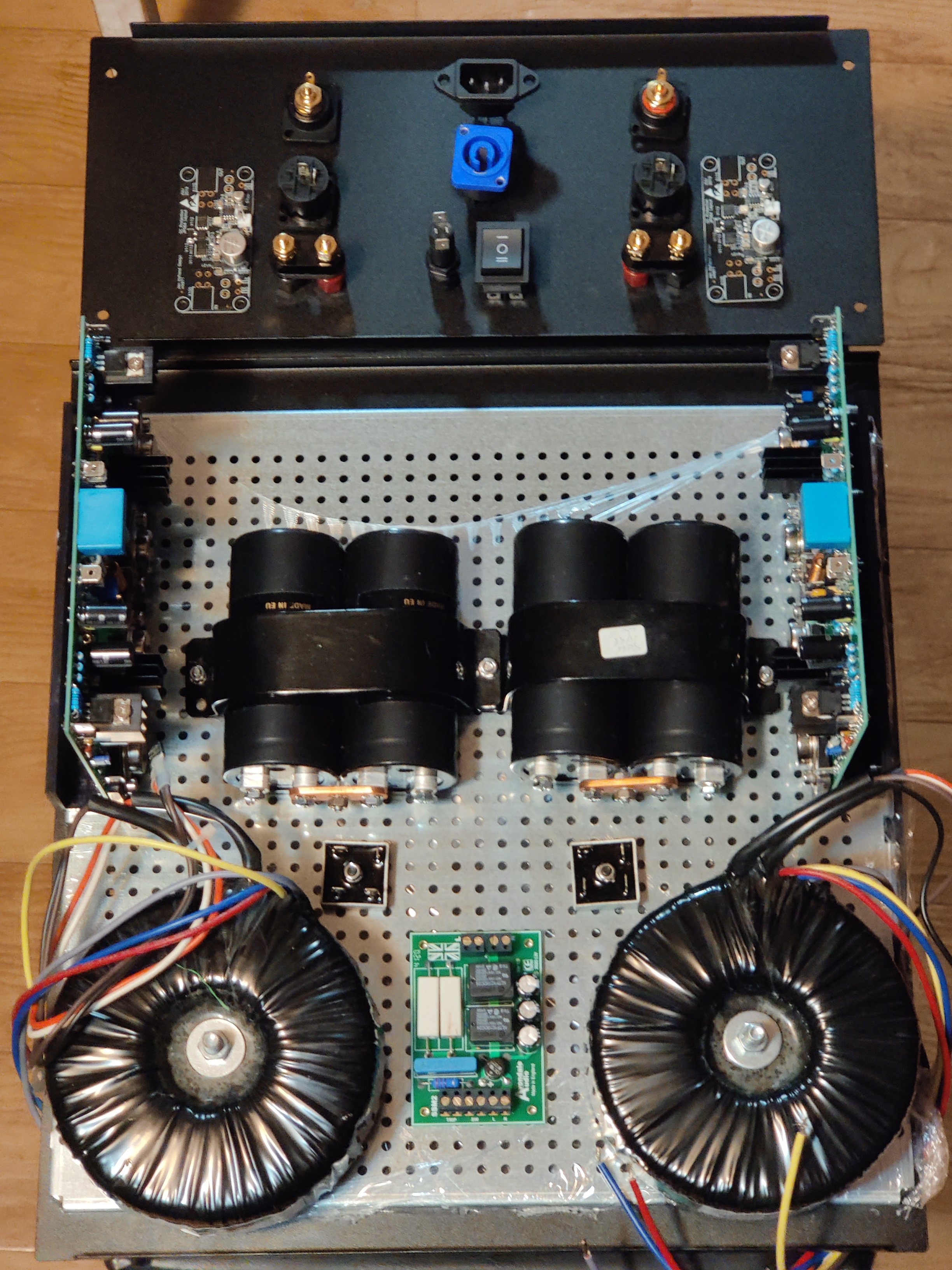

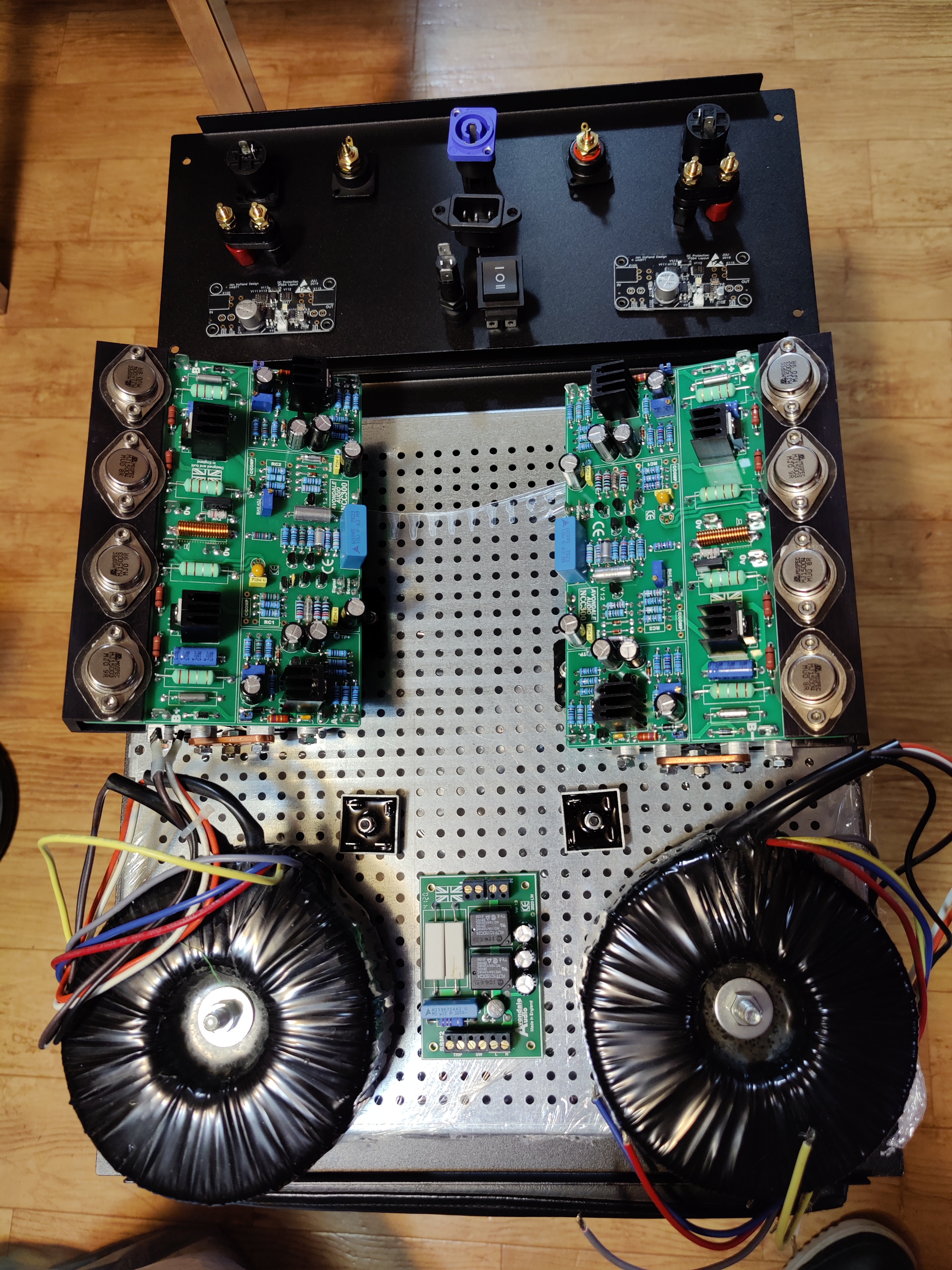

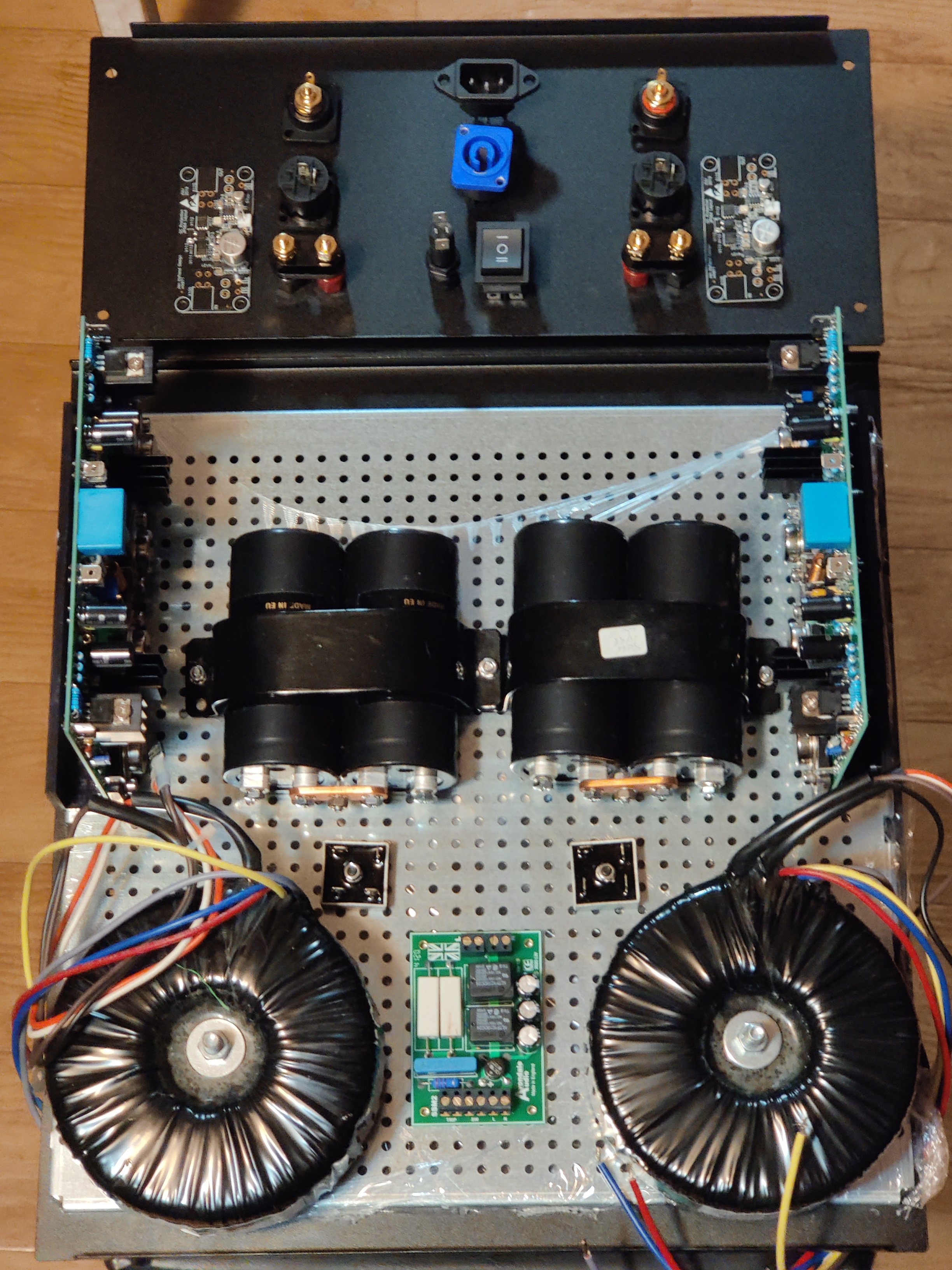

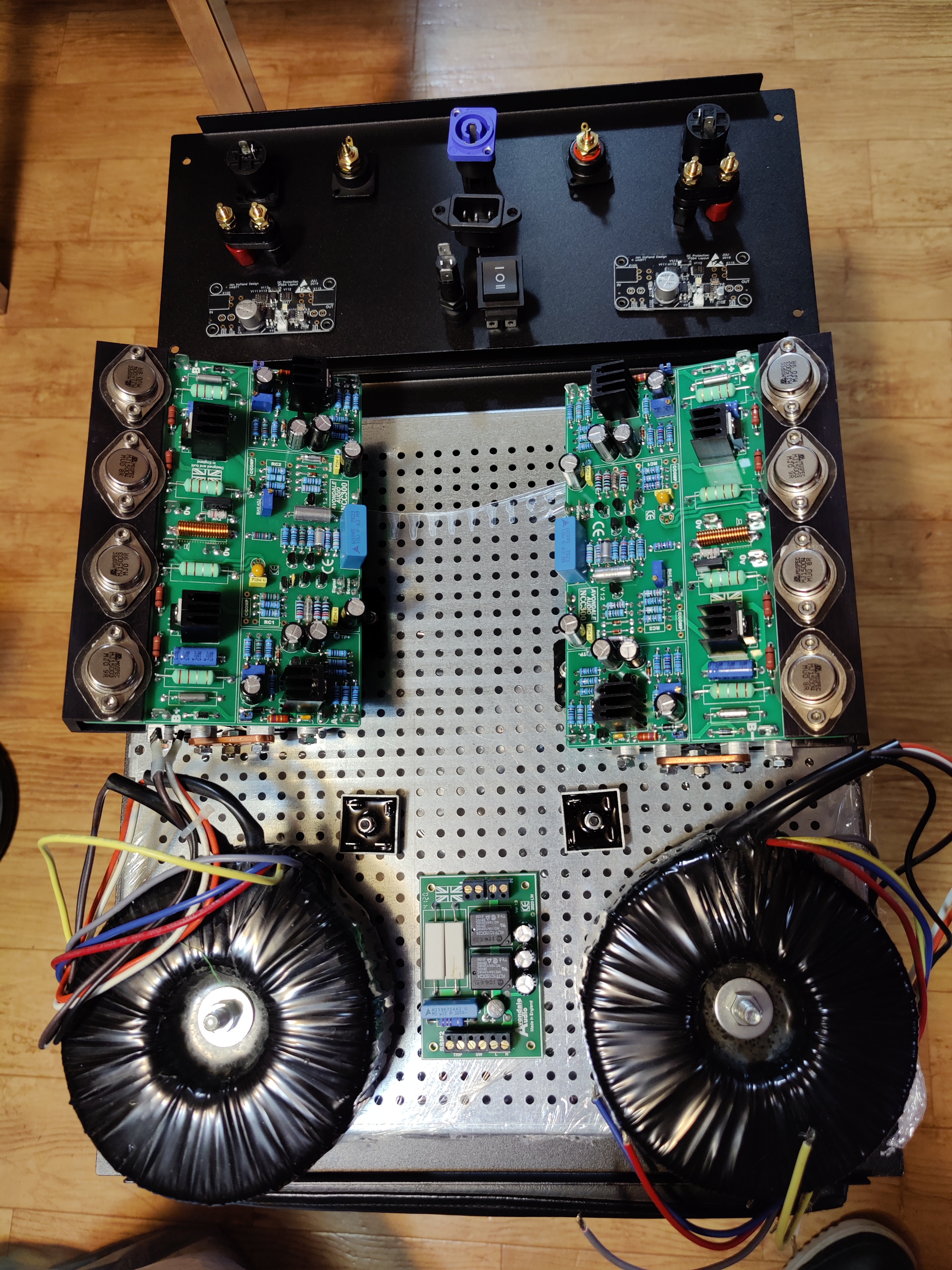

It's going to be put into a big 4U Dissipante case, so I have lots of space to play with. Here are a couple of possible layouts:

I'm not settled yet on whether to mount the NCC300 modules facing inward (as in the first picture) or facing up, with the caps hiding below. There's plenty of room in the case to do it either way. I like that the first layout keeps the amp modules far away from everything else, but I'm unsure if it's going to be trouble with them sideways like that. I'll probably go with #1, unless someone here convinces me that it's a terrible idea.

Regarding the components:

It's going to be put into a big 4U Dissipante case, so I have lots of space to play with. Here are a couple of possible layouts:

I'm not settled yet on whether to mount the NCC300 modules facing inward (as in the first picture) or facing up, with the caps hiding below. There's plenty of room in the case to do it either way. I like that the first layout keeps the amp modules far away from everything else, but I'm unsure if it's going to be trouble with them sideways like that. I'll probably go with #1, unless someone here convinces me that it's a terrible idea.

Regarding the components:

- The transformers from my friend had more secondaries than I needed for this build. I happened to have these Plitron 500VA units spare, each with dual 40V secondaries. I can join them to get 40V-0-40V, which is perfect for the NCC300.

- That's an Avondale SSM2.

- The bridge rectifiers are holding the place of Avondale modules with discrete Schottky diodes (kicking around here somewhere). The capacitors are 20,000µF Kemets.

- I prefer Neutrik connectors, but my buddy likes IEC for power and 5-way binding posts for speakers, so I'm adding both. (There's so much space on the back panel!) That rocker switch in the middle will toggle between power sockets.

- The speaker protection modules are the first gen of these. They're powered directly from the main DC supply, saving me the trouble of installing another transformer for a UPC1237 module.

- Avondale Bridge Rectifier with 20,000µF of Kemet caps

- HackerCap with ON-Semi rectifiers and 30,000µF of Chemi-Con caps (probably with 10mH inductors between each bank of caps)