James Evans

Bedroom Bodger

Tomorrow I will cut chamfer at the back of driver hole. Still waiting for leather to arrive for front baffle.

General speaker building question - what's the best strategy for cutting these internal driver hole chamfers?

Tomorrow I will cut chamfer at the back of driver hole. Still waiting for leather to arrive for front baffle.

I usually use a 45-degree bearing-guided router bit to cut the chamfers between the T-nuts/threaded inserts. The other way by hand is a rounded rasp/coarse file.General speaker building question - what's the best strategy for cutting these internal driver hole chamfers?

I want to get going on mine, but my garage is currently occupied by my non-starting Jag. I'm sending it off to the shop later this week, at which point I hope to commence with gluing, sanding, and oiling.

I've had it only a few months, and so far it's been fine. It's a 2003 XJ8 Vanden Plas that I got for a song, so I don't mind putting a bit of money into maintenance now and then.With a Jag you must miss access to your garage frequently (I sympathize we have a Land Rover...).

To be perfectly honest, I have never experimented with varying levels of stuffing. I always design the enclosure such that it is not entirely dependent on stuffing to achieve a higher apparent volume. I use stuffing mainly to kill internal reflections. I use just enough stuffing so that it doesn't move inside, but not so much that it is heavily compressed.Question for Ergo IX builders, how much stuffing and what type did you use? - I'm using a a nylon bulk fiber, a reasonable about but not tightly stuffed. I think James mentioned he used bats, which depending on the type could be quite a lot denser.

I read one data sheet that mentioned 1 lb of acoustic wool per cubic foot of enclosure. That seems a fair amount more than I am currently using, although I never actually weighed it.

Just curious, once I open mine up for the new XO I will experiment a bit and report.

Take care not to over-drive them, especially with very low bass. Despite their generous X-max, they are still a small driver and can suffer damage if you treat them like 12" woofers.That mid bass driver is a thing of wonder! Bass is super tight and goes a lot lower than you would expect for a driver/cabinet of this size.

The little Scan-speak has good thermal capacity relative to its size, and so should be able to reproduce just a touch over 100dB at 1m comfortably at, say, 1kHz. That's loud enough to be bad for your long term hearing. Its limitations kick in with LF that exceeds its physical excursion, which is very generous at +/- 9mm. I'd just visually check that when playing loudly that the cone is not exceeding 18mm of total travel. It is linear up to 13mm, so going beyond that will ramp up distortion even before you hit the end stops.I noticed these warnings a couple of times: what kind of damage and at what levels should we expect? I played things like this in a 25sqm room so loud that people can't speak and understand, is that too loud?

That's a simple fix. Use a suitably sized washer under each screw/bolt.BTW regarding suspension: my units show some small damages in the suspension under the screws. It seems the rubber get's dragged around the holes when fastening the screws...

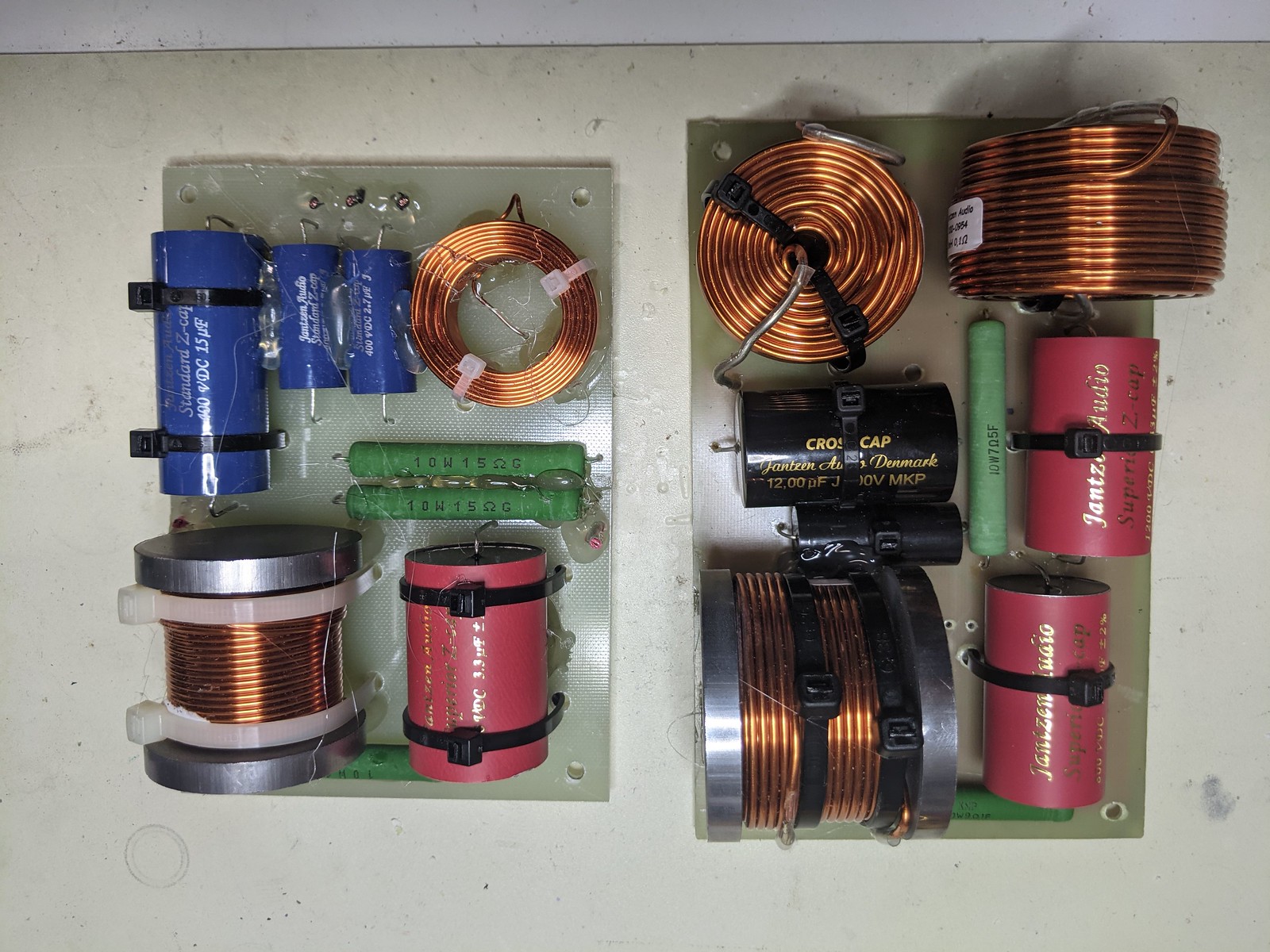

PCB Layout by Martin Carrington, on Flickr

PCB Layout by Martin Carrington, on Flickr