ToTo Man

the band not the dog

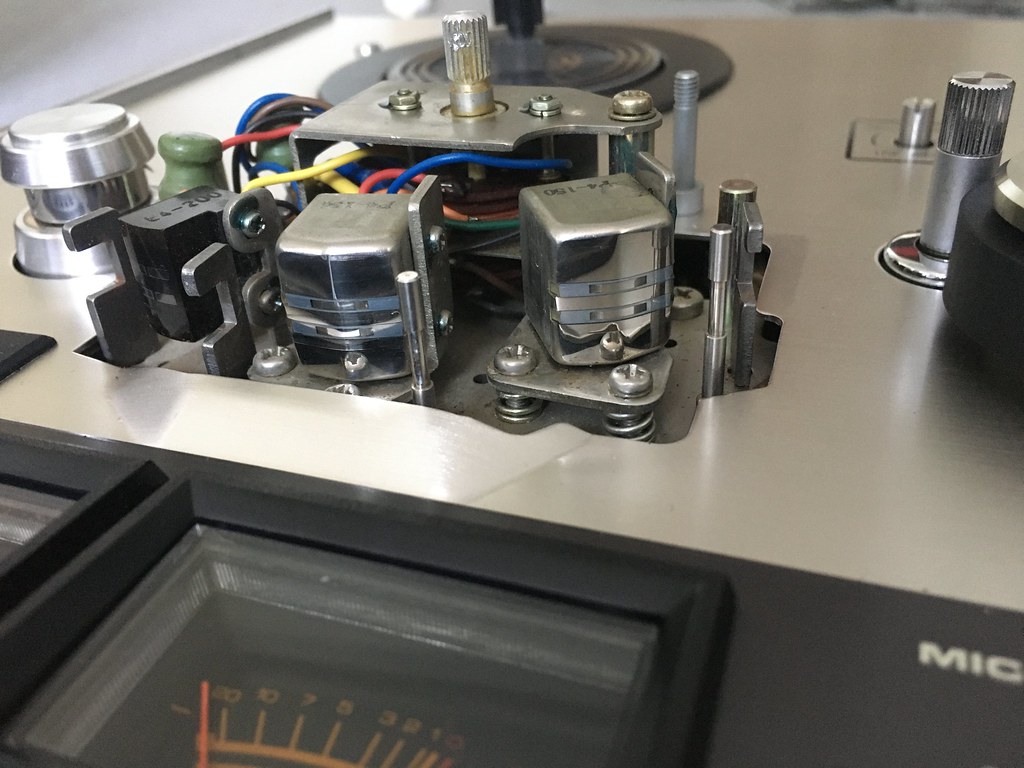

My uncle has gifted me his Revox B77 reel-to-reel. It's the 7.5ips/15ips 2-track version. Needless to say I'm chuffed!  He demoed to me working but says it hasn't been used in some time so will likely need a service.

He demoed to me working but says it hasn't been used in some time so will likely need a service.

I'm not entirely new to the B77. I bought a partly-restored one on eBay a few years ago but ended up returning it for a refund as it had a few minor issues that concerned me and I didn't want to go down the rabbit hole of spending more money on it. Things are different this time, my uncle has owned this B77 from new so I know its history and that it hasn't been hammered over the years, therefore I don't mind spending a bit of money on it if necessary to restore it to perfect working order.

I have a million questions to ask, but let's start with a few basic ones:

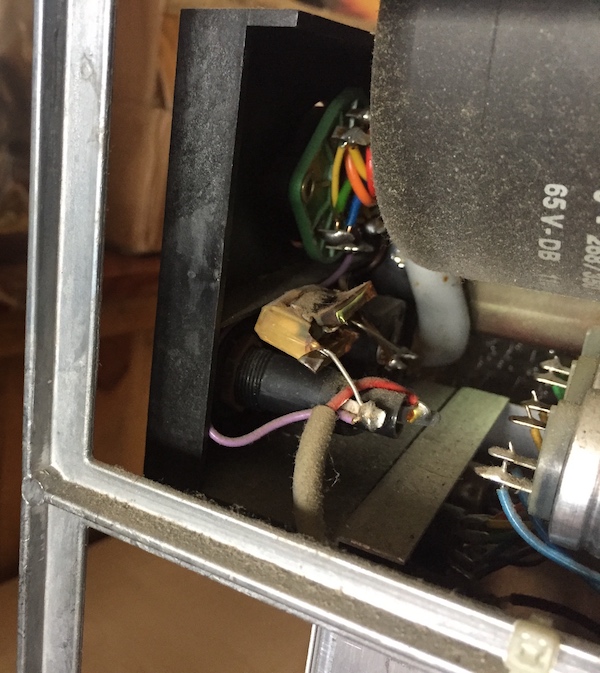

- Is there anything I should inspect before powering it up and using it? It's been a while since I researched the B77 but I have vague recollections of it containing 'Rifa' capacitors that have a tendency to smoke and/or explode. Should I be worried about this?

- The surface of the unit looks very dirty with ingrained dust. My dad wants to take a wet cloth to it but I'm concerned this will simply make things sticky and ingrain the dust even further. What is the best way to clean the unit?

- Lastly, and without getting ahead of myself, is there anyone within a reasonable distance of Glasgow (e.g. 75 mile radius) of Glasgow who could be trusted/recommended to restore a B77?

PS - When responding with advice, please assume my technical knowledge of the mechanics and electronics of R-2-Rs is nil .

.

Cheers.

I'm not entirely new to the B77. I bought a partly-restored one on eBay a few years ago but ended up returning it for a refund as it had a few minor issues that concerned me and I didn't want to go down the rabbit hole of spending more money on it. Things are different this time, my uncle has owned this B77 from new so I know its history and that it hasn't been hammered over the years, therefore I don't mind spending a bit of money on it if necessary to restore it to perfect working order.

I have a million questions to ask, but let's start with a few basic ones:

- Is there anything I should inspect before powering it up and using it? It's been a while since I researched the B77 but I have vague recollections of it containing 'Rifa' capacitors that have a tendency to smoke and/or explode. Should I be worried about this?

- The surface of the unit looks very dirty with ingrained dust. My dad wants to take a wet cloth to it but I'm concerned this will simply make things sticky and ingrain the dust even further. What is the best way to clean the unit?

- Lastly, and without getting ahead of myself, is there anyone within a reasonable distance of Glasgow (e.g. 75 mile radius) of Glasgow who could be trusted/recommended to restore a B77?

PS - When responding with advice, please assume my technical knowledge of the mechanics and electronics of R-2-Rs is nil

Cheers.

Last edited: