337alant

Negatively Biased

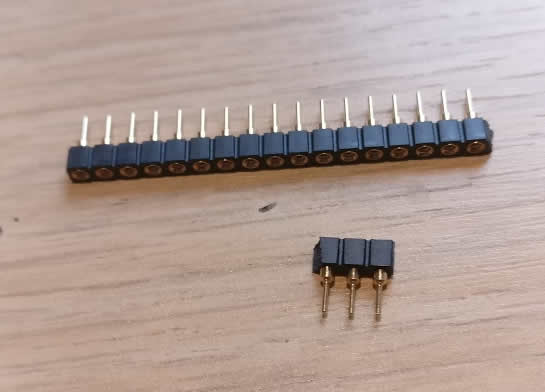

At the caravan for the week end but managed to fit in wiring one of the amps whilst the wife was chilling out .

.

20180408_134037 by Alan Towell, on Flickr

20180408_134037 by Alan Towell, on Flickr

20180408_140931 by Alan Towell, on Flickr

20180408_140931 by Alan Towell, on Flickr

Alan

20180408_134037 by Alan Towell, on Flickr

20180408_134037 by Alan Towell, on Flickr 20180408_140931 by Alan Towell, on Flickr

20180408_140931 by Alan Towell, on FlickrAlan

IMG_3315

IMG_3315 20180409_185128

20180409_185128