JohnW

pfm member

Is there any likelyhood that this chassis will have a fan included? I assume not, but given the bulging caps we've been hearing about for the original MDAC and in the interest of preserving something great, could an option for a temperature sensing and self enabling fan be added if it's not in the brief already?

Cheers

Sibbers,

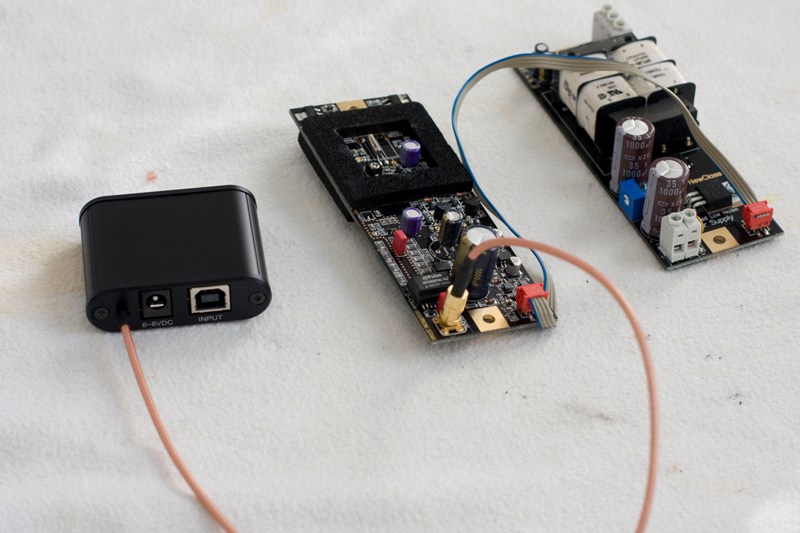

The operating Temperature of the MDAC is not the reason the caps are bulging (they are rated at 105 DegC) as I have prototype PCB's that have not been powered for years and yet the caps have bulged while in storage so its due to some internal chemical reaction.

The FDAC will operate cooler as its a larger chassis with much better ventilation - an important advantage of the larger case.