Tony L

Administrator

Is there a consensus view here on pfm regarding recapping old equipment? I've seen so many conflicting views across the net from Naim who seem to think it needs doing every decade to Sugden and Quad who will only replace stuff that is off spec/causing as fault condition to the Japanese who seem to want to replace as little as possible even on things as old as Leak tube amps. I know Rob went from a 'recap everything' mindset to finding the vast majority of capacitors pulled from even early '70s kit was still in spec.

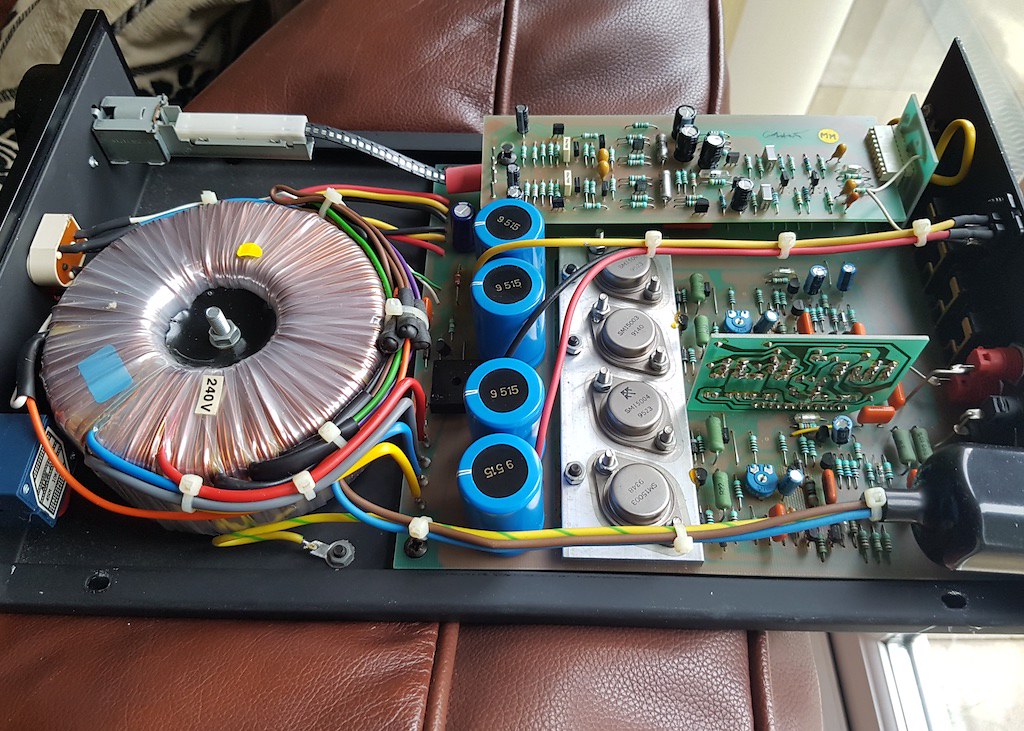

I'll give a couple of examples: I've very recently landed a very tidy Onix OA21S. It has to be one of the very last ones made as it has the same gold logo and speaker terminals as the OA401 and OA601 power amps that came out in 1990, so I guess it dates from then. It is allegedly low use. There is absolutely no evidence of bulging or leaking caps, nor of any servicing. I reset the bias (I googled it and found a thread on pfm telling me how to, I love when that happens!), it was a bit low, and DC offset is -15/-17mV which seems quite respectable. It works perfectly with no hum, crackles, switch on/off thump or any indication it is ill in any way, but it still has to be 26-27 years old! I'm tempted to leave it be as apparently Onix used very good long-lasting caps, but what is the consensus? I actually have another very much earlier OA21 that again appears to work fine, but I'll likely move this one on now as I don't need more than one!

I've also got a lovely 1973 Sony ST-5150 tuner that is the same, it just works perfectly with no hint of bulging or leaking caps and no hum. It looks like new inside! I have to admit I'd only do this one if it went wrong as it is less risk than an amp, it can't really hurt anything else downstream. I've got the matching amp too, again in lovely condition, but again I've been too scared to use it with valuable vintage speakers (I have no junk speakers!).

I'll give a couple of examples: I've very recently landed a very tidy Onix OA21S. It has to be one of the very last ones made as it has the same gold logo and speaker terminals as the OA401 and OA601 power amps that came out in 1990, so I guess it dates from then. It is allegedly low use. There is absolutely no evidence of bulging or leaking caps, nor of any servicing. I reset the bias (I googled it and found a thread on pfm telling me how to, I love when that happens!), it was a bit low, and DC offset is -15/-17mV which seems quite respectable. It works perfectly with no hum, crackles, switch on/off thump or any indication it is ill in any way, but it still has to be 26-27 years old! I'm tempted to leave it be as apparently Onix used very good long-lasting caps, but what is the consensus? I actually have another very much earlier OA21 that again appears to work fine, but I'll likely move this one on now as I don't need more than one!

I've also got a lovely 1973 Sony ST-5150 tuner that is the same, it just works perfectly with no hint of bulging or leaking caps and no hum. It looks like new inside! I have to admit I'd only do this one if it went wrong as it is less risk than an amp, it can't really hurt anything else downstream. I've got the matching amp too, again in lovely condition, but again I've been too scared to use it with valuable vintage speakers (I have no junk speakers!).