Right, so you've stripped the Linn, you understand the circuit, you need the components. The main component is going to be the transformer. It will be the majority of the cost, and is the thing that can kill you, so MAKE SURE YOU UNDERSTAND WHAT YOU'RE DOING!

It took me a while to get my head round these beasts, and I'm no expert, but for what it's worth, here's some info.

The transformer does what it says - it transforms mains voltage to a different one. That's it. We want a final voltage of around the 110v level, so we need a transformer that converts the supply voltage (240v) to 110v.

There are loads of different types, but the type we are using for this is a

toroidal transformer - it looks like a doughnut.

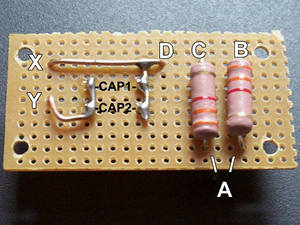

If you look for a toriodal transformer, they will come in a variety of flavours - centre tapped, dual secondaries, etc. Have a look below for a photo of a couple, and notice the scary number of wires coming out of them - particularly the one on the left.

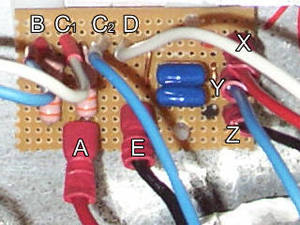

Look at the circuit diagram above - the bit labelled T1 is the transformer. If you look on the transformer itself, you'll see a similar picture, (see closeup), with the wire colours labelled.

Now as we're in the UK, we need the primaries (the left hand side of the diagram - where the supply comes in) to be set to 240V. Looking at the close up picture, you'll see that we have two sideways "U" with 0 at one side and 120v at the other. This is a dual primary setup. To make it work for 240 volts, we need to join the centre 120v (labelled grey below), and the centre 0v (labelled vio below). This then gives you the setup as shown in the circuit above.

The secondaries are more interesting, as there will be a variery of options. You may be lucky and just get a single set of leads out, like the one shown below - black and red. More likely there will be dual secondaries. In this case you may have two 55v secondaries, so join them in a similar way to the primaries - middle wires together. I found

this page quite handy for seeing the different configurations a transformer can be used in - remember that the wire colours will vary by manufacturer.

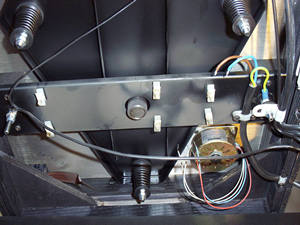

Mounting the transformer

The transformer should come with a mounting kit - this will comprise a bolt, nut and washer, plus a large steel "washer" and rubber gasket (I know it's not really a gasket, but that's the best description I can give). Both are about two thirds the size of the transformer.

Decide where the transfomer will go in your case, then mark a centre point. Drill a hole large enough to pass the bolt through. Then sit the transformer on the rubber "gasket", and sit the large steel plate/washer on top, with the "bump" downwards. Pass the bolt up from underneath, through the hole in the top plate, and fit washer and nut. Tighten, but not TOO hard.

Make sure that the bolt cannot touch the top of the case, as this might allow current to pass through the centre of the toroid - a very bad thing.

Wiring it up

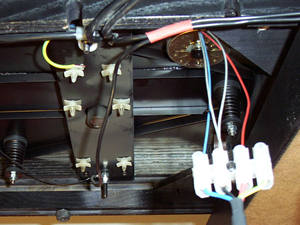

When joining the wire, make sure the connection is good - I soldered, then put insulation tape tound and finished off with a bit of shrinkwrap to keep things tidy. I have used crimp (spade) connectors on the ends that are going to the supply and board - the switch is bound to have these, and it makes things much easier to connect.

To use a spade connector, insert the wire into the top (narrow) end, and crimp it hard to hold the wire in place (best if you have the proper tool - you can buy sets with connectors and tool from most cheapy market tool stalls for about £2). I've also discovered some nice ones that you can solder the wire to, and use some long nose pliers to crimp on to the insulating later. See parts list below for more details. So, finally, in my case I'll be connecting the incoming mains voltage to my blue and brown wires, and the circuit board will be connected to the red and black wires.

Toroidal Tranformers

A couple of toroidal transformers, a 300VA on the left, and a 530VA on the right. Big and heavy!

Close up of Toroidal label

Here's an example label for a toroidal. This one's fairly simple - note the sticker covering the bottom half, as it's only got a single secondary.